#jaguarlandrover

Injuries from line assembly work may be reduced with the development of a special glove. Anthony Caggiano reports.

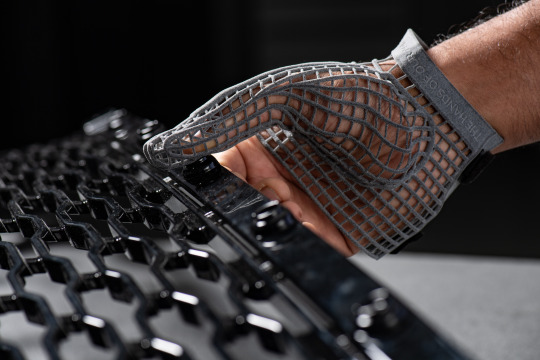

Jaguar Land Rover (JLR) is developing a 3D-printed glove designed to help minimise the risk of people developing a musculoskeletal disorder.

The glove is designed for people working on the production, for example those required to fit clips or fasteners into the chassis during vehicle assembly.

According to BBC News, 30% of all workplace injuries result in time off and account for a third of money paid in compensation to employees. They can also affect up to 40% in certain industries.

JLR’s 3D printing site at Gaydon, UK, designed a lattice-style structure to reduce muscle fatigue, but Alsop be flexible and comfortable enough to wear during an eight-hour shift. Using 3D computer aided design software, the team modelled designs in different densities using numerous materials for testing.

The first prototype was made with thermoplastic polyurethane (TPU), ULTRASINT, a material developed by BASF on a HP Multi Jet Fusion technology. A second prototype is being developed, which will include a foam pad using impact additive D30 – a polymer material, which absorbs impacts when placed under pressure. According to JLR, it will make the glove suitable for people who fit parts, such as door casings, using the palm of their hand.

The gloves will be used to support workers across JLR’s facilities in the short term, forming part of a wider future plan to deploy a range of technologies to assist those with muscle weakness or patients who suffer from physical or neurological disorders – helping employees return to work.

Image credits: Jaguar Landrover