#electrospinning

Electrospun sodium titanate speeds up the purification of nuclear waste water

Electrospun sodium titanate speeds up the purification of water based on selective ion exchange – effectively extracts radio-active strontium

With the help of this new method, waste water can be treated faster than before, and the environmentally positive aspect is that the process leaves less solid radio-active waste.

The properties of electrospun sodium titanate are equal to those of commercially produced ion-exchange materials.

“The advantages of electrospun materials are due to the kinetics, i.e. reaction speed, of ion exchange,” says Risto Koivula, a scientist in the research group Ion Exchange for Nuclear Waste Treatment and for Recycling at the Department of Chemistry at the University of Helsinki.

Post link

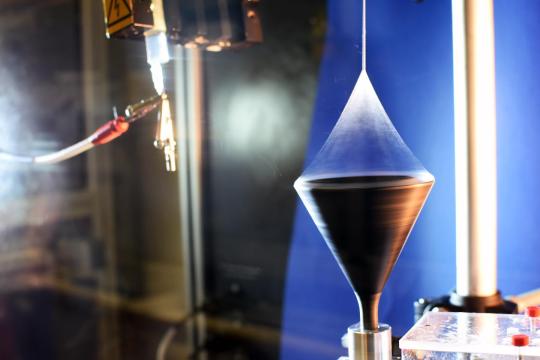

Electrospinning of a multifibrillar polyacrylonitrile fibre. Image credit: University of Bayreuth/Rennecke.

By Anthony Caggiano

University of Beyreuth, Germany, researchers have developed lightweight and strong polymer fibres through electrospinning.

Polyacrylonitrile is the chemical base of the fibre, of which a single one with a diameter of about 40,000nm consists of up to 4,000 ultra-thin fibrils.

One individual fibre is as thin as a human hair and can lift a weight of 30g without tearing – working out to about 150,000 times the weight of a fruit fly.

These fibrils are linked by small amounts of an additive, poly(ethylene glycol) bisazide (PEG-BA). Three-dimensional X-ray images show that the fibrils within the fibre are almost always arranged in the same longitudinal direction.

Bayreuth Polymer Scientist, Seema Agarwal, explained the process.

‘We prepared these multifibrillar polyacrylonitrile fibres in a laboratory for electrospinning at the University of Bayreuth and extensively tested them for their properties and behaviour. Their unique strength in combination with high toughness never ceased to fascinate us,’ Agarwal said.

Beyreuth Macromolecular Chemistry II research group leader, Andreas Greiner, said, ‘experiments on the high tensile strength of these fibres have furthermore revealed their high toughness. This means that each individual fibre can absorb a lot of energy.’

The overall properties were comparable to those of spider silk.

The researchers claim the polymer fibres are suited to technical components that are exposed to high loads. They enable innovative applications in a wide variety of fields, for example in textiles, aerospace, automotive engineering, or medical technology.

The fibres are also recyclable.

Other partners in the project were researchers at the Forschungszentrum Jülich, the Martin Luther University Halle-Wittenberg, the Fraunhofer-Institute for Microstructure of Materials and Systems (IMWS), the Rheinisch-Westfälische Technische Hochschule Aachen University, the Jiangxi Normal University, Nanchang, and ETH Zürich.

The results were published in Science. Find the paper here: