#tissue engineering

Advanced biomaterials with silk fibroin-bioactive glass to engineer patient-specific 3-D bone grafts

The complex architecture of bone is challenging to recreate in the lab. Therefore, advances in bone tissue engineering (BTE) aim to build patient-specific grafts that assist bone repair and trigger specific cell-signaling pathways. Materials scientists in regenerative medicine and BTE progressively develop new materials for active biological repair at a site of defect post-implantation to accelerate healing through bone biomimicry.

Rapidly initiation of new bone formation at the site of implantation is a highly desirable feature in BTE, and scientists are focused on fabricating grafts that strengthen the material-bone interface after implantation. Bioactive glass can bond with bone minutes after grafting, and silk fibroin, a natural fibrous protein has potential to induce bone regeneration. Hybrid materials that exploit these properties can combine the osteogenic potential and the load-bearing capacity for potential applications in large-load bone defect models.

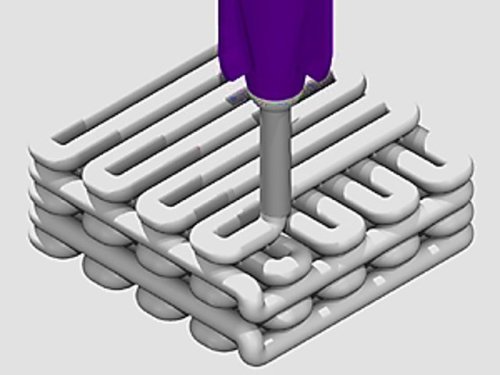

In a recent study, Swati Midha and co-workers developed a novel 3-D hybrid construct using silk-based inks with different bioactive glass compositions integrated to recreate a bone-mimetic microenvironment that supports osteogenic differentiation of bone marrow mesenchymal stem cell (BMSC) lines in the lab. Now published in Biomedical Materials, IOP Science, the scientists used direct writing instruments to produce the silk fibroin-gelatin-bioactive glass scaffolds (SF-G-BG). The results delivered appropriate cues to regulate the development of customized 3-D human bone constructs in vitro.

Post link

Artificial muscles powered by glucose

Artificial muscles made from polymers can now be powered by energy from glucose and oxygen, just like biological muscles. This advance may be a step on the way to implantable artificial muscles or autonomous microrobots powered by biomolecules in their surroundings. Researchers at Linköping University, Sweden, have presented their results in the journal Advanced Materials.

The motion of our muscles is powered by energy that is released when glucose and oxygen take part in biochemical reactions. In a similar way, manufactured actuators can convert energy to motion, but the energy in this case comes from other sources, such as electricity. Scientists at Linköping University, Sweden, wanted to develop artificial musclesthat act more like biological muscles. They have now demonstrated the principle using artificial muscles powered by the same glucose and oxygen as our bodies use.

The researchers have used an electroactive polymer, polypyrrole, which changes volume when an electrical current is passed. The artificial muscle, known as a “polymer actuator,” consists of three layers: a thin membrane layer between two layers of electroactive polymer. This design has been used in the field for many years. It works when the material on one side of the membrane acquires a positive electrical charge and ions are expelled, causing it to shrink. At the same time, the material on the other side acquires a negative electrical charge and ions are inserted, which causes the material to expand. The changes in volume cause the actuator to bend in one direction, in the same way that a muscle contracts.

Post link