#biopolymers

Mass production of biodegradable plastic

Introducing a simple step to the production of plant-derived, biodegradable plastic could improve its properties while overcoming obstacles to manufacturing it commercially, says new research from the University of Nebraska-Lincoln and Jiangnan University.

That step? Bringing the heat

Nebraska’s Yiqi Yang and colleagues found that raising the temperature of bio-plastic fibers to several hundred degrees Fahrenheit, then slowly allowing them to cool, greatly improved the bio-plastic’s normally lackluster resistance to heat and moisture.

Its thermal approach also allowed the team to bypass solvents and other expensive, time-consuming techniques typically needed to manufacture a commercially viable bio-plastic, the study reported.

Yang said the approach could allow manufacturers of corn-derived plastic – such as a Cargill plant in Blair, Nebraska – to continuously produce the biodegradable material on a scale that at least approaches petroleum-based plastic, the industry standard. Recent research estimates that about 90 percent of U.S. plastic goes unrecycled.

Post link

Silk bio-ink could help advance tissue engineering with 3-D printers

Advances in 3-D printing have led to new ways to make bone and some other relatively simple body parts that can be implanted in patients. But finding an ideal bio-ink has stalled progress toward printing more complex tissues with versatile functions – tissues that can be loaded with pharmaceuticals, for example. Now scientists, reporting in the journalACS Biomaterials Science & Engineering, have developed a silk-based ink that could open up new possibilities toward that goal.

Most inks currently being developed for 3-D printing are made of thermoplastics, silicones, collagen and gelatin or alginate. But there are limits to how these inks can be used. For example, the temperatures, pH changes and crosslinking methods that may be required to toughen some of these materials can damage cells or other biological components that researchers would want to add to the inks.

Additives, such as cytokines and antibiotics, are useful for directing stem cell functions and controlling infections, respectively. To address these bio-ink limitations, David L. Kaplan and colleagues turned to silk protein and developed a way to avoid these harsh processing conditions.

The researchers combined silk proteins, which are biocompatible, and glycerol, a non-toxic sugar alcohol commonly found in food and pharmaceutical products. The resulting ink was clear, flexible, stable in water, and didn’t require any processing methods, such as high temperatures, that would limit its versatility. The researchers say the novel material could potentially be used in biomedical implants and tissue engineering.

Post link

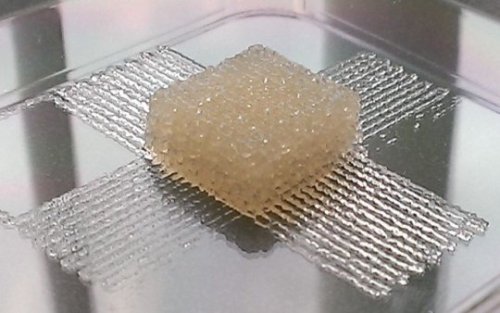

SCAFFOLD

Researchers want to develop biocompatible polymers that would serve as scaffolding that helps regrow tissue, replacing damaged or missing flesh and organs in patients. A Swedish team developed the high-molecular-weight polymer shown above, which fluoresces strongly under near-infrared light, a part of the spectrum where most flesh is transparent. In lab rats, the researchers monitored the scaffolding mats with near-IR light and observed that it was colonized by rat tissue and blood vessels.

Credit:Adv. Funct. Mater. 2015, DOI: 10.1002/adfm.201500351

(Enter our photo contest here)

Related C&EN Content:

Post link

New Research in Green Plastics Uses Tree Resin

New research into renewable, green plastics is using tree resin rather than petroleum. University of South Carolina researcher Chuanbing Tang has given evergreen a new meaning. The polymers come from evergreen trees such as pine and fir. These materials are loaded with hydrocarbons, which through the polymerization process can be turned into various types of plastics. Tang says that these wood products are useful because “they’re a rich source of the cycloaliphatic and aromatic structures that make good materials after polymerization, and they have the rigid molecular structures and hydrophobicity that materials scientists know work well.“

Not only are these products ‘green’ from the beginning, they also end ‘green’. Since these polymers are derived from living materials, they are biodegradable. “With a polymer framework derived from renewable sources, we’re able to make materials that should break down more readily in the environment” says Tang.

—Adam

Photo:Wildeherb.com

Further Reading:

http://www.sciencedaily.com/releases/2013/02/130220170631.htm

http://www.newswise.com/articles/turning-pine-sap-into-ever-green-plastics

Post link