#rocket pack

Using hot glue to attach styrofoam supports for the Sintra frame that will become the “fin” on the back of the rocket pack. As always, a cardboard mockup serves as my guiding light.

Post link

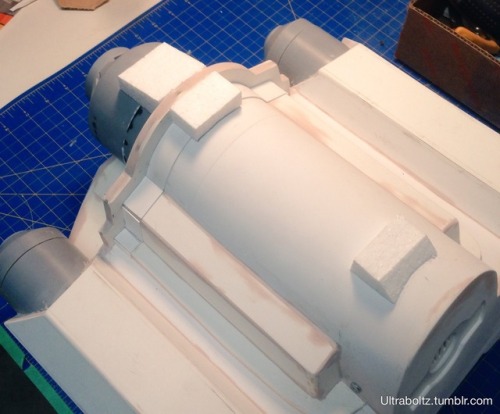

Here’s where we’re at! Was on vacation for two weeks, am now back and in the shop (real life allowing). Structure is 99% built up, and starting to bury this thing in Bondo. That cardboard-looking piece on the top (left photo) is cardboard. It’s a template. Gotta do Bondo-big and some other details before I can build that part.

Post link

Got the “butt” glued on. It’s a little rough around the edges, literally, but I’m hoping some putty, bondo, and sanding will sort that out nicely. Also building up the details on the back of the pack. Trying styrofoam core for the shape and then Sintra glued on top of that to give a nice hard surface. Might be tricky!

Post link

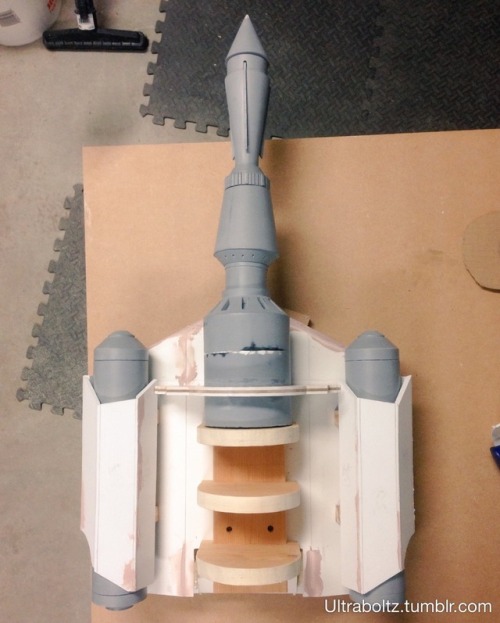

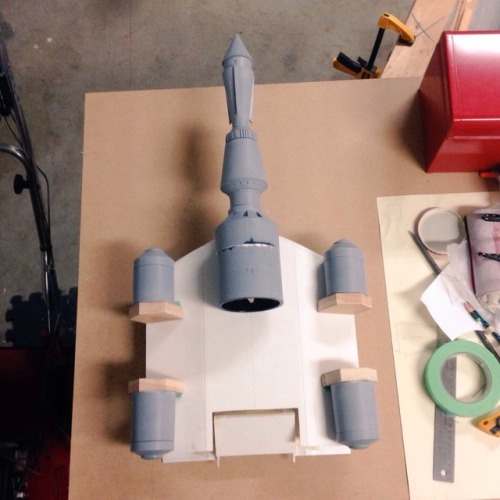

Got a solid 8hrs in the shop yesterday (such a treat!) Lots of smaller things done–bondo, sanding, putty, bolted the mounting clips on… and got some big stuff blocked in, too!

Really starting to take shape now.

Post link

Building the form up piece by piece! I realized I’m going to have to find a very solid way to attach the clips that will secure the pack to my back–it’s no featherweight! Trying to build light, but all the pieces add up. Probably around 10lbs when finished.

Post link

Starting to cut out and assemble the pieces to build the body of the rocket pack now. To get the right thickness I glued layers of Sintra together and then cut out the shapes on the scroll saw afterwards. The first time I attempted multi-layer parts I tried to glue them together after I’d cut them out–which was a fail. Impossible to get them to match perfectly in shape, and zero tolerance for shifting during clamping.

Post link

Still a long way to go, but you can see where it’s headed!

P.S filler primer is the cat’s meow.

Post link

Got this all glued together yesterday, just a little bit of filling with epoxy putty and then it’s ready for primer!

Post link

Alright, here’s a quick summary of the painting process for the rocket pack. First, primer. After primer, lay down some silver/aluminum wherever you think you’re going to want the fancy paint chip. I just do it for high-visibility areas, and anywhere where I need a lot of metal to show through. It’ll make more sense later. Read on!

Step 2: With the silver on, I use Crayola kids “Project Glue” as a masking substance. Just paint that stuff right onto the prop wherever you want your simulated paint chips and scratches to show the silver underneath. Definitely test whatever glue you use before you put it on your prop! I use kids glue because it peals off super easy.

Step 3: So once the masking is all done, it’s time to start laying down your base colours. Boba’s rocket pack in ROTJ actually has the most preschool color scheme you’ve ever seen. Thankfully, weathering is a beautiful thing.

Step 4: details, stencils, stuff. These are just made by verrry carefully cutting stencils out of painters tape–though there are a million ways to make stencils.

Step 5: The good stuff! I start with a “grunge” pass. I’ll do a wash with a sort of oily black-brown, and then airbrush on the accumulation of dirt, dust, carbon, etc. Remember, weathering tells the story of your prop, and it shows if you just put it on randomly. Story is king!

Step 6: last but certainly not least is the “scratches” pass. My favourite. This is where I use a fine pen-knife/exacto blade to peel off the kids glue and reveal the beautiful silver underneath. I ALSO do a fine detail pass with a brush and some Testors silver model paint to put in all the really fine scratches and worn corners and stuff. There are tons of techniques for weathering, and no rules, so have fun! Write your prop’s story. Hope some of this is useful!

Post link