#friction

A Penetrating Look at Ice Friction

A new approach for studying friction on ice helps explain why the ease of sliding depends strongly on temperature, contact pressure, and speed.

[…]

In Latvia, where bobsledding, luge, and skeleton are popular, ice can be more than just “slippery.” The local language has another term slīdamība—roughly translated as “slideability”—which refers to the ease of movement on a surface. This terminology signifies the awareness that sliding on ice depends on multiple factors—something physicists have had trouble explaining despite 160 years of effort. Previous work has focused on the water layer that forms between the ice surface and the sliding object, say, an ice skate. However, this model does not show why friction is higher near the ice melting point than it is at lower temperatures (Fig. 1). A new study of the solid properties of ice may provide a solution. Rinse Liefferink from the University of Amsterdam and colleagues have performed a series of experiments, in which they measure both the friction of a sliding object and the hardness of ice over a wide range of conditions [1]. The observations show that the hardness decreases as the temperature increases, leading to a high-friction “ploughing” behavior once the sliding object is able to penetrate the softer ice surface. This novel approach to studying ice friction could help in developing technologies that improve safety for winter drivers or give an edge to winter athletes.

Post link

New composite materials prolong the service life of spare parts for equipment and vehicles

Studies have shown that hybrid powder materials based on natural layered silicates developed by the chemists of the Far Eastern Federal University (FEFU) and the Far Eastern Branch of the Russian Academy of Sciences (FEB RAS) decrease the friction ratio in metals sevenfold. These new materials offer new prospects for the development of more efficient anti-friction additives, increasing the durability of spare parts for equipment and vehicles.

The work was carried out by research associates of the School of Natural Sciences and Engineering School of FEFU, as well as the Institute of Chemistry of FEB RAS. The research running led by Nikolay Shapkin, professor of the Department of General, Inorganic, and Organoelement chemistry at FEFU. The results were published in Inorganic Materials.

The scientists report two hybrid composite materials based on natural layered silicates and plant products. The first was obtained from nontronite silicate isolated from Popov Island in the vicinity of Vladivostok and modified with alkaline rice husk hydrolysate. Experiments have shown that applying this powder reduces the deterioration of friction-producing parts 2.5 to seven times. Another material based on vermiculite from Karelia and modified with regular cellulose reduced the friction ratio 1.6 times.

Post link

Graphene-wrapped diamond ball bearings cut friction to virtually nothing

A method that reduces friction between two surfaces to almost zero on macroscopic scales has been demonstrated by US researchers. The phenomenon, which was discovered accidentally, works by combining nanodiamonds with sheets of graphene, which curl around the nanodiamonds to form ‘nanoscrolls’ that lubricate the two surfaces. As friction wastes so much energy in all sorts of mechanical devices this discovery has huge potential to save both energy and money.

Post link

Graphene Roll-Ups Make Friction Disappear, Could Revolutionize Machine Engineering

Chalk another amazing ability up for the supermaterial graphene. It seems the atom-thick sheets of linked carbon atoms can virtually eliminate friction.

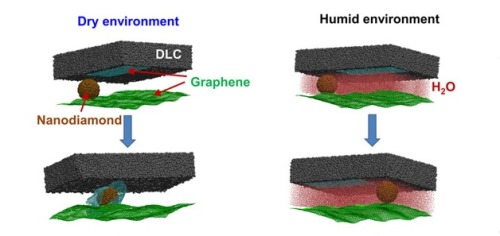

The simulation above depicts the graphene-lubricant discovery–blue graphene sheets roll up to encase gold nanodiamonds as a surface of black diamond-like carbon slides over. Once the graphene wraps into so-called nanoscrolls around the nanodiamonds, the sheets make friction disappear.

“The nanoscrolls combat friction in very much the same way that ball bearings do by creating separation between surfaces,” said Argonne National Lab researcher Sanket Deshmukh. Learn more and see photos below.

Post link

Simulations lead to design of near-frictionless material

Argonne scientists used Mira to identify and improve a new mechanism for eliminating friction, which fed into the development of a hybrid material that exhibited superlubricity at the macroscale for the first time. Argonne Leadership Computing Facility (ALCF) researchers helped enable the groundbreaking simulations by overcoming a performance bottleneck that doubled the speed of the team’s code.

While reviewing the simulation results of a promising new lubricant material, Argonne researcher Sanket Deshmukh stumbled upon a phenomenon that had never been observed before.

“I remember Sanket calling me and saying ‘you have got to come over here and see this. I want to show you something really cool,’” said Subramanian Sankaranarayanan, Argonne computational nanoscientist, who led the simulation work at the Argonne Leadership Computing Facility (ALCF), a DOE Office of Science User Facility.

They were amazed by what the computer simulations revealed. When the lubricant materials–graphene and diamond-like carbon (DLC)–slid against each other, the graphene began rolling up to form hollow cylindrical “scrolls” that helped to practically eliminate friction. These so-called nanoscrolls represented a completely new mechanism for superlubricity, a state in which friction essentially disappears.

Post link

Slip sliding away: Graphene and diamonds prove a slippery combination

Scientists at the U.S. Department of Energy’s Argonne National Laboratory have found a way to use tiny diamonds and graphene to give friction the slip, creating a new material combination that demonstrates the rare phenomenon of “superlubricity.”

Led by nanoscientist Ani Sumant of Argonne’s Center for Nanoscale Materials (CNM) and Argonne Distinguished Fellow Ali Erdemir of Argonne’s Energy Systems Division, the five-person Argonne team combined diamond nanoparticles, small patches of graphene – a two-dimensional single-sheet form of pure carbon – and a diamond-like carbon material to create superlubricity, a highly-desirable property in which friction drops to near zero.

According to Erdemir, as the graphene patches and diamond particles rub up against a large diamond-like carbon surface, the graphene rolls itself around the diamond particle, creating something that looks like a ball bearing on the nanoscopic level. “The interaction between the graphene and the diamond-like carbon is essential for creating the ‘superlubricity’ effect,” he said. “The two materials depend on each other.”

Post link

Sex fact: “Double Bagging” or wearing two condoms at once actually is less effective. The two condoms rub together causing friction and are more likely to tear.

God… the friction alone