#mymsepost

Alloys: 6061 Aluminum

Among the most popular aluminum alloys, 6061 aluminum is an alloy in the 6000 series of aluminum alloys: those heat treatable alloys where the principle alloying elements are magnesium and silicon. Because it is so popular, 6061 aluminum is also one of the least expensive of the aluminum alloys.

Highly resistant to corrosion, this alloy can be tempered a variety of different ways to achieve the desirable properties. Different tempers can alter the workability, weldability, and strength. T6 is one of the most common tempers (solution heat treated and artificially aged), but other tempers include O (annealed), T1 (cooled from elevated temperature shaping process and naturally aged), and T4 (solution heat-treated and naturally aged).

6061 aluminum is composed of over 95% aluminum with small or trace amounts of silicon, iron, copper, manganese, magnesium, chromium, zinc, and titanium added in. Magnesium is the largest alloying element, at up to 1.2% maximum, followed by silicon at 0.80% maximum. It is very often extruded but is also suitable for hot forging.

While not as high strength as some of the other aluminum alloys, 6061 is still highly versatile and used in a wide variety of applications: railway car components; boat or aircraft structures; other structural components such as bridges; pipes; wheels; cans; and SCUBA tanks.

Sources/Further Reading: (1) ( 2 - image 2 ) (3) (4) (5)

Post link

Polymers: Polyphenylene oxide

Though its technical name is poly(2,6-dimethylphenylene oxide) it is most commonly known as poly(phenylene oxide) or PPO. A condensation polymer, the polymerization of PPO produces water as a byproduct. It is a type of polyphenylene and is often grouped alongside polyphylene ethers as well.

PPO is one of many high-performance polymers known as engineering thermoplastics. These polymers have higher glass transition temperatures, making them temperature resistant. However, these polymers are often more crystalline, and therefore more brittle. In order to help with processing of PPO and to increase the toughness, almost all commercially available forms of the polymer are blended with polystyrene (such as high-impact polystyrene, or HIPS).

Applications of PPO (or, more commonly, blends of PPO and polystyrene) include those shown on the chart above. PPO is often used in applications where a polymer is desired but high heat resistance is also necessary, such as certain structural applications, electronics, and medical equipment (such as sterilizable instruments). Another common usage is in air separation membranes for the generation of nitrogen, an application which uses hollow fibers to create a membrane.

Sources/Further Reading: ( 1 - image 1 ) ( 2 - image 2 ) ( 3 - image 3 ) (4) (5)

Post link

Island of Stability

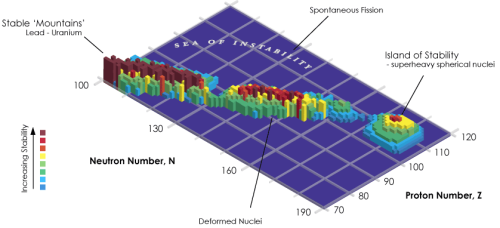

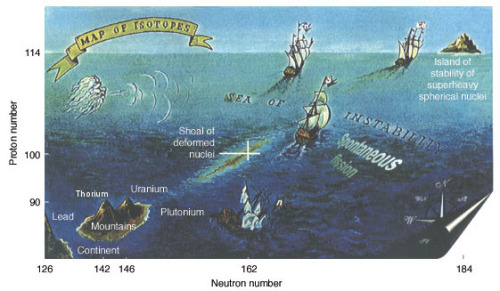

In nuclear physics, the island of stability is defined as “the prediction that a set of heavy isotopes with a near magic number of protons and neutrons will temporarily reverse the trend of decreasing stability in elements heavier than uranium”. Elements beyond rutherfordium (element 104) are considered superheavy elements, and the most long-lived ones are expected to exist on the so called island of stability with extremely long half-lives.

While adding more nucleons tends to make elements unstable, the stability of elements doesn’t depend only on the number of protons and neutrons in its nucleus, but also the arrangementof said protons and neutrons. This is where the magic numbers come in: for protons 2, 8, 20, 28, 50, 82, 114, 120, 126 and for neutrons 2, 8, 20, 28, 50, 82, 126, 184. Evidence of these magic numbers can be seen in naturally occurring stable elements. In fact, lead, the last stable element, is considered to be double magic, with 82 protons and 126 neutrons (specifically lead-208).

However, despite all this, the existence of superheavy and relatively stable isotopes has not yet been demonstrated. Some physicists think that the half-lives of elements on the island of stability will only be on the order of minutes, hours, or days, while others theorize they will be on the order of 109 years. Stability is relative - none of the elements past lead are ever expected to be completely stable.

Sources: (Top Image) (2) (Bottom Image) (4)

Post link

Polymers: Polysulfones

A category of polymers technically defined as any polymer which contains a sulfonyl group, the term polysulfone is actually most often used in reference to polyarylethersulfones, in which the following structure is present: aryl-SO2-aryl. These polymers are thermoplastics, and known for their toughness and stability at high temperatures.

Polysulfones are amorphous polymers typically prepared through condensation polymerizations and are rigid and high-strength. They stand up well in high-pressure environments and are often considered to be high-performance polymers. These polymers are often semi-transparent and resistant to creep and deformation at high temperatures under continuous loads.

These polymers are fairly uncommon, due to the relatively high costs of production and the raw materials involved, and as such applications of polysulfones tend to be highly specialized. Because of their high service temperatures, they are sometimes used as flame retardants, or in medical applications requiring autoclave or steam sterilization. Another common application is in the form of membranes, with controllable poor sizes.

Sources/Further reading: ( 1 - image 1 ) ( 2 - image 2 ) (3) (4)

Post link

Additive Manufacturing: Directed Energy Deposition

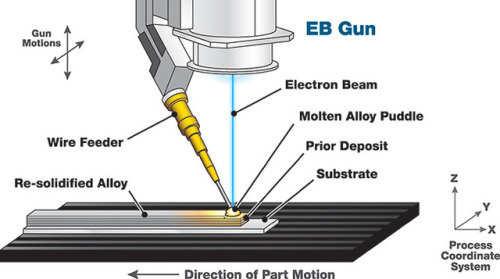

A type of metal additive manufacturing process, directed energy deposition (DED) uses either powders or wires to create finished parts. Unlike most other AM processes, DED is commonly used to repair components or add additional material, rather than simply create new parts.

Types of directed energy deposition, or other names for the process, include directed metal deposition (DMD), laser metal deposition (LMD), laser-engineered net shaping (LENS), and laser consolidation (LC).

DED uses a deposition head to feed either powder or wire into a laser (or electron) beam that melts the material, thereby building up the surface of the part. Because it is not melting material that has already been laid down (such as in powder bed fusion), DED can build on existing parts. Powders can also be mixed, utilizing different material properties. Using different, compatible materials can increase wear, corrosion, and oxidation resistance, one of the benefits of DED.

Limited in size only by the beam manipulation system, another benefit is that DED can produce relatively large parts, as shown in the top right image above: Sciaky (a US 3D printing company) can make 5-meter-large parts in a variety of different materials. Because of the method of deposition, there is also little to no waste involved. However, DED is also a relatively slow process, which takes much longer than other methods to produce parts.

Sources: ( 1 - image 1 ) ( 2 - image 3 ) ( 3 - images 2 and 4 ) (4)

Post link

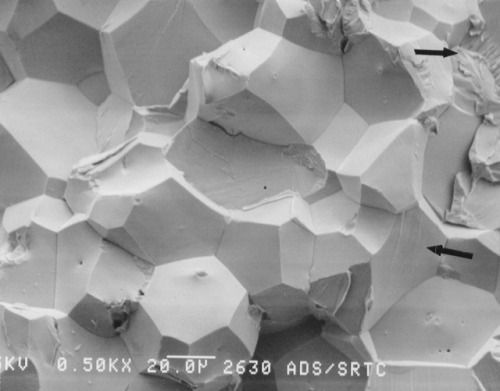

Materials Characterization: Scanning Electron Microscopy

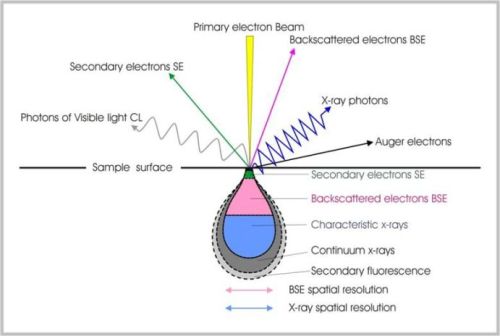

One of the many instruments that uses electrons to view the surface of a material is the scanning electron microscope, or SEM. In order to achieve a higher resolution and greater magnification than is possible with ordinary light, scientists turned to electrons and the resolution of an SEM can approach a few nanometers. SEMs don’t actually snap a picture of the surface but rather provide the contrastthat produces an image. The resulting image, called a micrograph, is very similar to what you would expect if you could actually “see” the surface. SEM images are always monochrome but are often edited to produce false color images (sometimes similar to the real material, sometimes vastly different).

How though, do electrons produce an image? It all depends on how they react with the sample. An SEM contains a series of magnetic lenses that focus the beam of electrons similarly to how glass lenses focus light in an optical microscope. This beam of electrons then hits the surface of the sample and can undergo either inelasticorelastic scattering, resulting in the emission of electrons. It is these emitted electrons that are analyzed. Secondary electrons are low-energy electrons that are ejected from the specimen atoms by inelastic scattering. Backscattered electrons are high-energy electrons from the original electron beam that are reflected or back-scattered by elastic scattering.

Some of the most common methods for producing the electron beam itself are thermionic tungsten, LaB6, and hot and cold field emission.

Unlike an optical microscope, an SEM has a few sample requirements. For one, the material has to be vacuum compatible. For another, it helps to have a conducting material. If your material isn’t a conductor it must be coated with a thin conducting film (usually around ten nanometers) of carbon, gold, or some other metal.

Thanks to the fantastic images it can provide, the scanning electron microscope is one of the most widely used tools for materials characterization.

Post link

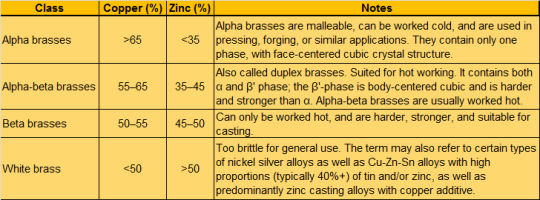

Alloys: Brass

An alloy of copper and zinc that has been known about since ancient times, brass is stronger and more durable than its base components, though not as strong as steel. It has stuck around for so long because it’s easy to work with, though the malleability depends upon the zinc content, and is used in decorations and applications where low friction is required.

Brass is a substitutional alloy, typically composed of around 67% copper and 33% zinc. Alloys with less zinc are occasionally called red brass while alloys with more zinc (above 45%) are known as white brasses (and are not commonly used industrially). The table below shows some of the common classifications.

Other elements commonly added to brass include tin, iron, arsenic, antimony, aluminum and potentially small amounts of manganese, silicon, and phosphorus. Lead is also a common additive, though it is becoming less common thanks to growing concerns about its toxicity.

Aside from the properties mentioned above there are many more reasons why brass is a desirable metal. The high copper content makes brass anti-microbial, making it ideal for use in commonly touched items. Brass is also fairly corrosion resistant, allowing it to be used in plumbing. Instruments made of brass are also extremely common thanks to the alloys workability and durability.

Check out this link for a list of common brass alloys and this one for more in depth information on the properties of various alloys.

Image Sources: Top left,top right,middle left,middle right,bottom left,bottom right

Post link

Ceramics: Magnesium diboride

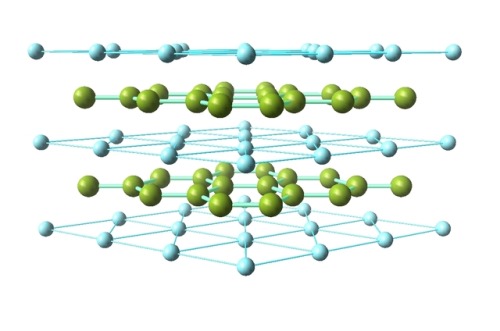

Classified as a simple binary compound, magnesium diboride (MgB2) is also sometimes known as an intermetallic superconductor. It has a hexagonal crystal structure, which forms two-dimensional layers of boron in a graphite-like structure between the triangular layers of magnesium (as seen in the two images above).

MgB2‘s biggest claim to fame is its status as a relatively inexpensive superconductor. Among conventional superconductors (those that are phonon-mediated), it has one of the highest critical temperatures, at around 39 K. Though it had been known as a material to scientists for some time, its superconductivity was not discovered until 2001. Aside from being a high-temperature superconductor, MgB2 also has more than one superconducting energy gap, something theorized but rarely seen experimentally.

The bulk, polycrystalline form of the material can be easily made by exposing solid boron to magnesium vapor at high temperatures. Single crystals of the material are more difficult to form, but can be done so under high pressure. Thin films are often made through hybrid physical-chemical vapor deposition.

Applications (or possible applications) of MgB2 often take advantage of its superconductivity, such as in MRIs and tokamaks, but the material does have other suggested uses. The compound burns completely when ignited in oxygen, and so has been proposed for usage as a fuel in ramjets, or in blast-enhanced explosives and propellants.

Sources: ( 1 - image 3 ) (2) (3) (4) (5) (6)

Post link

Materials Testing: Tensile Tests

Extremely useful for determining various mechanical properties, the tensile test (or tension test, as it is also called) is one of the most common methods of materials testing.

A tensile test is carried out by taking a sample of a material and subjecting it to increasing tension, stretching the sample until failure. This simple test results in the graph shown above (or something similar, depending on the material) called a stress-strain diagram. The elongation of the sample is determined with relation to the force required to produce such stretching and, knowing the cross-sectional area of the sample, the resulting stress and strain can be calculated and graphed.

This simple diagram gives a surprising number of mechanical properties, including the Modulus of Elasticity (or Young’s Modulus),yield strength,ultimate strength (also called ultimate tensile strength or tensile strength), and ductility (depending on the elongation before failure). Though less common, the stress-strain diagram can also be used to calculate the modulus of toughness and of resilience.

Along with the many properties that can be determined, another reason that tensile tests are so popular is that they can be used for almost any material. Depending on said material, the specimen is usually shaped similar to those in the bottom right image in what is called a ‘dog bone’ sample. The top left and bottom left images show brittle and ductile failure, respectively.

Image sources: top left,top right,bottom left,bottom middle,bottom right

Post link

Types of Luminescence

Despite the numberof typesof luminescencealready covered, there are still several more to talk about.

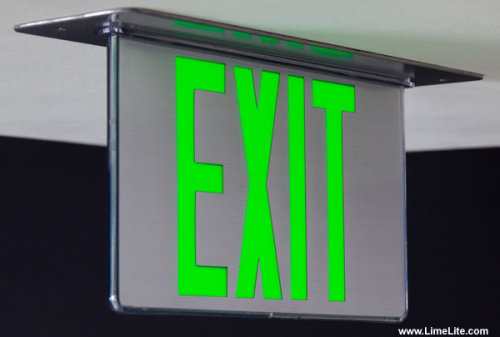

Electroluminescence is when light is emitted due to the passage of an electric current or a strong electric field and is usually seen in semiconductors (such as LEDs). Electroluminescent technologies use relatively low power, though at high voltage, and can be quite thin. This form of luminescence is responsible for the two central images shown above, as well as the Indiglo feature available in many watches.

Similar to electroluminescence, cathodoluminescence is a form of luminescence in which electrons impact a luminescent material and cause the emission of photons which may have wavelengths in the visible spectrum and is mainly seen in semiconductors. One well known example is in cathode ray tubes in televisions. Optical cathodoluminescence microscopes can be used similarly to scanning electron microscopes to examine internal structures of materials.

Radioluminescence occurs by bombardment of materials with ionizing radiation such as beta particles. It is used in applications where light must be produced for long periods without external energy sources. The upper left hand images are illuminated using radioluminescence.

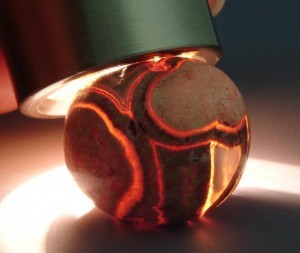

Thermoluminescence is a form of luminescence that is exhibited by certain crystalline materials when previously absorbed energy is re-emitted as light upon heating of the material. It is not the same as black body radiation, when a material glows due to heating. It’s main application is in dating buried objects that have been heated in the past, such as pottery. The upper right image and bottom image illustrate thermoluminescence.

Finally, crystalloluminescence is luminescence produced during crystallization, but it has not been widely studied and not much is known about it.

Sources:Electroluminescence,Cathodoluminescence,Radioluminescence,Thermoluminescence,Crystalloluminescence

Post link

Alloys: Steel

According to Dictionary.com, steel is “any of various modified forms of iron, artificially produced, having a carbon content less than that of pig iron and more than that of wrought iron, and having qualities of hardness, elasticity, and strength varying according to composition and heat treatment: generally categorized as having a high, medium, or low-carbon content”.

Perhaps the most well known alloy around, as well as one of the most common materials in the world, steel is essentially iron with a small percentage of carbon (and, on occasion, one or more other elements). Not enough carbon and you’re stuck with wrought iron, too much carbon and you get cast iron. The graph above is a binary iron-carbon phase diagram that goes from zero percent carbon to about 6.5 percent, illustrating the various phases that can form.

Steel has been known about since ancient times, some pieces dating back to 1800 BC, but it was the invention of the Bessemer process during the industrial revolution that really popularized the alloy. (Technically, similar methods had been used before, particularly in China and Japan, but Henry Bessemer invented the modern method, industrializing it and obtaining a patent in 1856.)

Mainly used in construction, the alloy has been used for almost every possible application: from office furniture to steel wool, from bulldozers to washing machines, and from wires to watches, the possibilities are pretty much endless. Steel is also one of the world’s most-recycled materials, able to be used more than once, with a recycling rate of over 60% globally.

The addition of carbon allows the steel to be stronger than the iron it’s made from. Adding nickel and manganese increases its tensile strength, chromium increases hardness and melting temperature, and vanadium also increases hardness while making it less prone to metal fatigue. Stainless steel has at least eleven percent chromium, whereas Hadfield steel (which resists wearing) contains twelve to fourteen percent manganese. Check out theselinks for more information on the effects of adding certain elements.

Sources:1 (top images),2 (bottom images)

Post link

Ruthenium in Steel

Though not a commercially available alloying element, largely due to its cost, the effects of the addition of ruthenium to steel have been considered and researched. In general, the addition of small amounts of ruthenium (and other platinum group metals, such as palladium) has been found to increase the corrosion resistance of certain stainless steels, especially in non-oxidizing environments.

Sources/Further Reading: (1) (2)

Post link

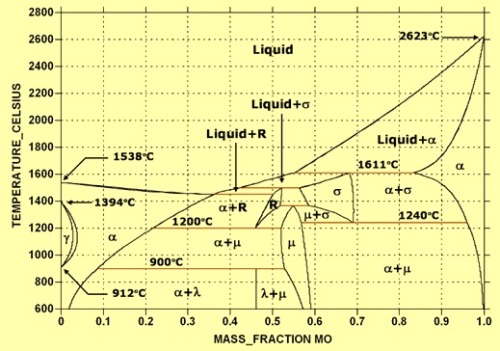

Molybdenum in Steel

Often referred to as moly by steelmakers and metallurgist, molybdenum is an important alloying element in many steels, granting hardenability, corrosion resistance, and other favorable properties. Molybdenum is often mined in the form of molybdenite(MoS2) and added in the form of ferromolybdenum,molybdenum trioxide, or sometimes scrap.

Molybdenum is a ferrite stabilizer, lowering the solubility of carbon in austenite, forming strong carbides, and decreasing the temperature range at which austenite exists. Less than 1% of the element in steel is needed to form these carbides that increase the strength and hardness of the resulting material, though in the presence of stronger carbide formers molybdenum carbides are less likely. Steels with molybdenum carbides can be used in high temperature environments and are resistant to hydrogen blistering.

A strong hardenability agent, only about 0.5% molybdenum or less is added to heat treatable steels to increase their final strength and hardness. For heat treatable steels containing chromium, the addition of molybdenum can alleviate their susceptibility to temper embrittlement.

In austenitic stainless steels, molybdenum helps increase corrosion and pitting resistance, notably in marine environments or against sulfuric acid. In martensitic stainless steels molybdenum increases pitting resistance, and in ferritic stainless steels it improves resistance to marine environments and some organic acids.

Finally, up to 9% molybdenum can be added to certain tool steels, increasing hardness, wear resistance, and strength at elevated temperatures. The M-series of high speed steels, specifically, contain between 3.5-9.5% molybdenum.

Sources/Further Reading: (1) (2) ( 3 - image 1 ) (4) (5)

Post link

Minerals: Wulfenite

A lead molybdenite mineral with the formula PbMoO4, wulfenite is typically found in the form of thin tabular crystals that range from orange-red to yellow-orange in color, though it can also be brown. It was named for Austrian mineralogist Franz Xaver Freiherr von Wulfen, though it wasn’t named until decades after his death.

Wulfenite crystallizes in the tetragonal crystal system. It is a secondary ore for both lead and molybdenum but, though it can be used to extract both of these elements, other, more commons ores are typically used. As such, wulfenite is usually only used by collectors.

For more in depth information about wulfenite, check out what mindat.org,webmineral.com,minerals.net, and handbookofmineralogy.org have to say about it.

Sources: (1) ( 2 - image 4 ) ( 3 - image 1 )

Image sources: ( 2 and 3 )

Post link