#nanocomposites

Sintering atomically thin materials with ceramics now possible

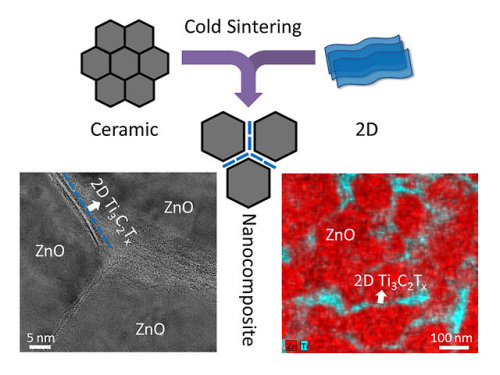

For the first time, researchers have created a nanocomposite of ceramics and a two-dimensional material, opening the door for new designs of nanocomposites with such applications as solid-state batteries, thermoelectrics, varistors, catalysts, chemical sensors and much more.

Sintering uses high heat to compact powder materials into a solid form. Widely used in industry, ceramic powders are typically compacted at temperatures of 1472 degrees Fahrenheit or higher. Many low-dimensional materials cannot survive at those temperatures.

But a sintering process developed by a team of researchers at Penn State, called the cold sintering process (CSP), can sinter ceramics at much lower temperatures, less than 572 degrees F, saving energy and enabling a new form of material with high commercial potential.

“We have industry people who are already very interested in this work,” said Jing Guo, a post-doctoral scholar working in the group of Clive Randall, professor of materials science and engineering, Penn State. “They are interested in developing some new material applications with this system and, in general, using CSP to sinter nanocomposites.” Guo is first coauthor on the paper appearing online in Advanced Materials.

Post link

Digitally programmable perovskite nanowire-block copolymer composites

One-dimensional nanomaterials with highly anisotropicoptoelectronic properties can be used within energy harvesting applications, flexible electronics and biomedical imaging devices. In materials science and nanotechnology, 3-D patterning methods can be used to precisely assemble nanowires with locally controlled composition and orientation to allow new optoelectronic device designs. In a recent report, Nanjia Zhou and an interdisciplinary research team at the Harvard University, Wyss Institute of Biologically Inspired Engineering, Lawrence Berkeley National Laboratory and the Kavli Energy Nanoscience Institute developed and 3-D printed nanocomposite inks composed of brightly emitting colloidal cesium lead halide perovskite (CsPbX3, where X= Cl, Br, or I) nanowires.

They suspended the bright nanowires in a polystyrene-polyisoprene-polystyrene block copolymer matrix and defined the nanowire alignment using a programmed print path. The scientist produced optical nanocomposites that exhibited highly polarized absorption and emission properties. To highlight the versatility of the technique they produced several devices, including optical storage, encryption, sensing and full color displays. The work is now published on Science Advances.

Post link

Eco-friendly composite catalyst and ultrasound removes pollutants from water

The research team of Dr. Jae-woo Choi and Dr. Kyung-won Jung of the Korea Institute of Science and Technology’s (KIST, president: Byung-gwon Lee) Water Cycle Research Center announced that it has developed a wastewater treatment process that uses a common agricultural byproduct to effectively remove pollutants and environmental hormones, which are known to be endocrine disruptors.

The sewage and wastewater that are inevitably produced at any industrial worksite often contain large quantities of pollutants and environmental hormones (endocrine disruptors). Because environmental hormones do not break down easily, they can have a significant negative effect on not only the environment but also the human body. To prevent this, a means of removing environmental hormones is required.

The performance of the catalyst that is currently being used to process sewage and wastewater drops significantly with time. Because high efficiency is difficult to achieve given the conditions, the biggest disadvantage of the existing process is the high cost involved. Furthermore, the research done thus far has mostly focused on the development of single-substance catalysts and the enhancement of their performance. Little research has been done on the development of eco-friendly nanocomposite catalysts that are capable of removing environmental hormones from sewage and wastewater.

The KIST research team, led by Dr. Jae-woo Choi and Dr. Kyung-won Jung, utilized biochar, which is eco-friendly and made from agricultural byproducts, to develop a wastewater treatment process that effectively removes pollutants and environmental hormones. The team used rice hulls, which are discarded during rice harvesting, to create a biochar** that is both eco-friendly and economical. The surface of the biochar was coated with nano-sized manganese dioxide to create a nanocomposite. The high efficiency and low cost of the biochar-nanocomposite catalyst is based on the combination of the advantages of the biochar and manganese dioxide.