#hydrogen fuel

New coating is a breakthrough for hydrogen fuel

Photocatalysis using particles in water is a promising technology for generating fuels from sunlight. One major obstacle to producing these solar fuels cheaply and abundantly, though, is that it requires semiconductors that are efficient but prone to corrosion.

In a breakthrough that overcomes this challenge, the lab of Shu Hu, assistant professor of Chemical & Environmental Engineering, has found a solution with a first-of-its-kind coating. The results are published in the Proceedings of the National Academy of Sciences.

Water-splitting systems—which break water down to hydrogen and oxygen—need semiconductor materials with narrow bandgaps (a property allowing for absorbing more sunlight), which efficiently converts solar energy to chemical energy. While these materials can easily capture sunlight, they all corrode under illumination via self-reduction or self-oxidation. It’s a challenge that researchers have spent more than a half-century trying to solve. Strategies to protect these materials tend to limit their abilities to separate the charges of negative electrons and positive holes, a process that is essential to photocatalysis but harder to achieve than it is for other systems, such as solar cells. Typically, layers designed to guard these systems protect only one of the system’s two electrodes, namely the cathode or anode, limiting it to allow for the transport of either electron or hole—but not both.

Post link

Tripling the efficiency of solar-based hydrogen fuel generation with metallic nanostructures that slow down light

Hydrogen gas, an important synthetic feedstock, is poised to play a key role in renewable energy technology; however, its credentials are undermined because most is currently sourced from fossil fuels, such as natural gas. A KAUST team has now found a more sustainable route to hydrogen fuel production using chaotic, light-trapping materials that mimic natural photosynthetic water splitting.

The complex enzymes inside plants are impractical to manufacture, so researchers have developed photocatalysts that employ high-energy, hot electrons to cleave water molecules into hydrogen and oxygen gas. Recently, nanostructured metals that convert solar electrons into intense, wave-like plasmon resonances have attracted interest for hydrogen production. The high-speed metal plasmons help transfer carriers to catalytic sites before they relax and reduce catalytic efficiency.

Getting metal nanoparticles to respond to the entire broadband spectrum of visible light is challenging. “Plasmonic systems have specific geometries that trap light only at characteristic frequencies,” explains Andrea Fratalocchi, who led the research. “Some approaches try to combine multiple nanostructures to soak up more colors, but these absorptions take place at different spatial locations so the sun’s energy is not harvested very efficiently.”

Post link

Research uncovers mechanism behind water-splitting catalyst

Caltech researchers have made a discovery that they say could lead to the economically viable production of solar fuels in the next few years.

For years, solar-fuel research has focused on developing catalysts that can split water into hydrogen and oxygen using only sunlight. The resulting hydrogen fuel could be used to power motor vehicles, electrical plants, and fuel cells. Since the only thing produced by burning hydrogen is water, no carbon pollution is added to the atmosphere.

In 2014, researchers in the lab of Harry Gray, Caltech’s Arnold O. Beckman Professor of Chemistry, developed a water-splitting catalyst made of layers of nickel and iron. However, no one was entirely sure how it worked. Many researchers hypothesized that the nickel layers, and not the iron atoms, were responsible for the water-splitting ability of the catalyst (and others like it).

To find out for sure, Bryan Hunter (PhD ‘17), a former fellow at the Resnick Institute, and his colleagues in Gray’s lab created an experimental setup that starved the catalyst of water. “When you take away some of the water, the reaction slows down, and you are able to take a picture of what’s happening during the reaction,” he says.

Post link

New efficient, low-temperature catalyst for hydrogen production

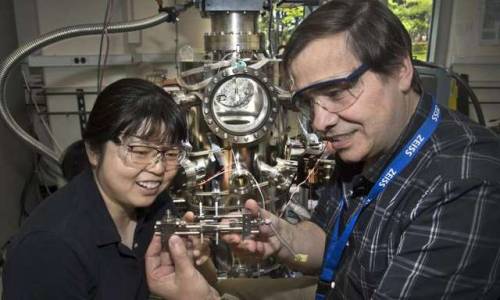

Scientists have developed a new low-temperature catalyst for producing high-purity hydrogen gas while simultaneously using up carbon monoxide (CO). The discovery-described in a paper set to publish online in the journal Science on Thursday, June 22, 2017-could improve the performance of fuel cells that run on hydrogen fuel but can be poisoned by CO.

“Thiscatalyst produces a purer form of hydrogen to feed into the fuel cell,” said José Rodriguez, a chemist at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory. Rodriguez and colleagues in Brookhaven’s Chemistry Division-Ping Liu and Wenqian Xu-were among the team of scientists who helped to characterize the structural and mechanistic details of the catalyst, which was synthesized and tested by collaborators at Peking University in an effort led by Chemistry Professor Ding Ma.

Because the catalyst operates at low temperature and low pressure to convert water (H2O) and carbon monoxide (CO) to hydrogen gas (H2) and carbon dioxide (CO2), it could also lower the cost of running this so-called “water gas shift” reaction.

“With low temperature and pressure, the energy consumption will be lower and the experimental setup will be less expensive and easier to use in small settings, like fuel cells for cars,” Rodriguez said.

Post link