#coatings

Superstrong Al alloys may change manufacturing processes for automobiles, aerospace devices

Purdue University researchers have developed a superstrong material that may change some manufacturing processes for the aerospace and automobile industries.

The Purdue team, led by Xinghang Zhang, a professor in Purdue’s School of Materials Engineering, created high-strength aluminum alloy coatings. According to Zhang, there is an increasing demand for such materials because of their advantages for automakers and aerospace industries.

“We have created a very durable and lightweight aluminum alloy that is just as strong as, and possibly stronger than, stainless steel,” Zhang said. “Our aluminum alloy is lightweight and provides flexibility that stainless steel does not in many applications.”

Another member of the Purdue team, Yifan Zhang, a graduate student in materials engineering, said the aluminum alloy they created could be used for making wear- and corrosion-resistant automobile parts such as engines and coatings for optical lenses for specialized telescopes in the aerospace industry.

Post link

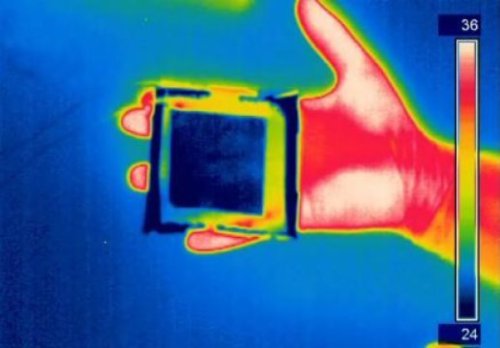

Thermal camouflage disguises hot and cold

Hunters don camouflage clothing to blend in with their surroundings. But thermal camouflage – or the appearance of being the same temperature as one’s environment – is much more difficult. Now researchers, reporting in ACS’ journal Nano Letters, have developed a system that can reconfigure its thermal appearance to blend in with varying temperatures in a matter of seconds.

Most state-of-the-art night-vision devices are based on thermal imaging. Thermal cameras detect infrared radiation emitted by an object, which increases with the object’s temperature. When viewed through a night-vision device, humans and other warm-blooded animals stand out against the cooler background. Previously, scientists have tried to develop thermal camouflage for various applications, but they have encountered problems such as slow response speed, lack of adaptability to different temperatures and the requirement for rigid materials. Coskun Kocabas and coworkers wanted to develop a fast, rapidly adaptable and flexible material.

Post link

Let it rain! New coatings make natural fabrics waterproof

Fabrics that resist water are essential for everything from rainwear to military tents, but conventional water-repellent coatings have been shown to persist in the environment and accumulate in our bodies, and so are likely to be phased out for safety reasons. That leaves a big gap to be filled if researchers can find safe substitutes.

Now, a team at MIT has come up with a promising solution: a coating that not only adds water-repellency to natural fabrics such as cotton and silk, but is also more effective than the existing coatings. The new findings are described in the journal Advanced Functional Materials, in a paper by MIT professors Kripa Varanasi and Karen Gleason, former MIT postdoc Dan Soto, and two others.

“The challenge has been driven by the environmental regulators” because of the phaseout of the existing waterproofing chemicals, Varanasi explains. But it turns out his team’s alternative actually outperforms the conventional materials.

“Most fabrics that say ‘water-repellent’ are actually water-resistant,” says Varanasi, who is an associate professor of mechanical engineering. “If you’re standing out in the rain, eventually water will get through.” Ultimately, “the goal is to be repellent—to have the drops just bounce back.” The new coating comes closer to that goal, he says.

Post link

New coating is a breakthrough for hydrogen fuel

Photocatalysis using particles in water is a promising technology for generating fuels from sunlight. One major obstacle to producing these solar fuels cheaply and abundantly, though, is that it requires semiconductors that are efficient but prone to corrosion.

In a breakthrough that overcomes this challenge, the lab of Shu Hu, assistant professor of Chemical & Environmental Engineering, has found a solution with a first-of-its-kind coating. The results are published in the Proceedings of the National Academy of Sciences.

Water-splitting systems—which break water down to hydrogen and oxygen—need semiconductor materials with narrow bandgaps (a property allowing for absorbing more sunlight), which efficiently converts solar energy to chemical energy. While these materials can easily capture sunlight, they all corrode under illumination via self-reduction or self-oxidation. It’s a challenge that researchers have spent more than a half-century trying to solve. Strategies to protect these materials tend to limit their abilities to separate the charges of negative electrons and positive holes, a process that is essential to photocatalysis but harder to achieve than it is for other systems, such as solar cells. Typically, layers designed to guard these systems protect only one of the system’s two electrodes, namely the cathode or anode, limiting it to allow for the transport of either electron or hole—but not both.

Post link

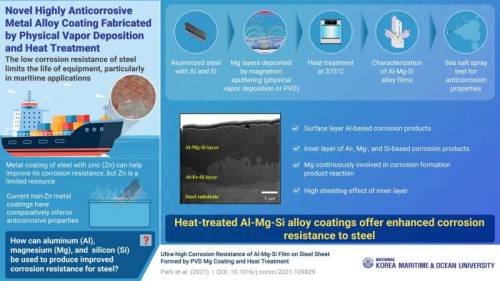

Suiting up with Al-Mg-Si: New protective coating for steel in ships and marine and coastal facilities

One of the most common methods of improving the corrosion resistance of steel is coating it with other metals such as aluminum (Al). But the use of Al in marine applications is limited owing to its tendency to react with chloride ions in sea water, leading to corrosion. The addition of other elements, such as magnesium (Mg) and silicon (Si), to form an alloyed coating is a promising way around this problem. But Mg cannot be easily deposited as a coating using the conventional method of dipping the steel into a hot bath of metal salts.

In a recent study published in Corrosion Science, scientists have developed a new protocol for Al-Mg-Si coating of steel. “When I served in the navy, I was constantly looking at rusting machinery. Since then, I have become fully engaged in research on how to produce better anti-corrosive steels,” says Professor Myeong-Hoon Lee of the Korea National Maritime and Ocean University, who guided the study. This study was made available online on September 9, 2021 and was published in Volume 192 of the journal in November 2021.

Post link

Researchers find whimsy at the nano scale

At extremely small scales, looks can be deceiving. While at first glance you might see lily pads floating on a tranquil pond, this image is actually a clever adaptation of a snapshot taken on a scanning electron microscope.

In reality, the green spots are only a few micrometers across—smaller than width of a human hair. They make up a surface coating that was developed to limit the transmission of SARS-CoV-2, the virus that causes COVID-19. The coating is composed of a silver-based material applied to a glass surface. The lotus flower, though, was some added artistic flair courtesy of image-editing software.

Mohsen Hosseini, Ph.D. candidate in chemical engineering, and William Ducker, professor of chemical engineering, recently won an award in the National Nanotechnology Coordinated Infrastructure (NNCI) image contest with this image. Both Hosseini and Ducker are affiliated with the Macromolecules Innovation Institute (MII).

Their win was in the category “most whimsical.”

Post link

An optical coating like no other

For more than a century, optical coatings have been used to better reflect certain wavelengths of light from lenses and other devices or, conversely, to better transmit certain wavelengths through them. For example, the coatings on tinted eyeglasses reflect, or “block out,” harmful blue light and ultraviolet rays.

But until now, no optical coating had ever been developed that could simultaneously reflect and transmit the same wavelength, or color.

In a paper in Nature Nanotechnology, researchers at the University of Rochester and Case Western Reserve University describe a new class of optical coatings, so-called Fano Resonance Optical Coatings (FROCs), that can be used on filters to reflect and transmit colors of remarkable purity.

In addition, the coating can be made to fully reflect only a very narrow wavelength range.

Post link

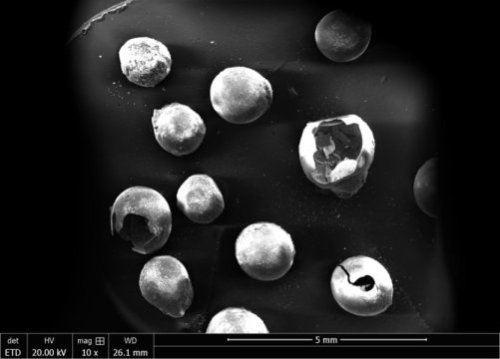

Antireflective Coating: Sugar-based carbon hollow spheres that mimic moth eyes

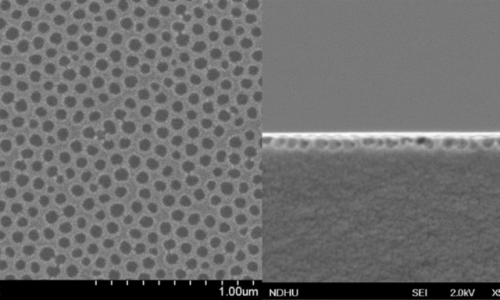

They are not to eat, but this insect-inspired ordered monolayer of hollow carbon spheres may be a new, green and extremely lightweight antireflective coating that almost perfectly absorbs microwave radiation

Antireflective coatings are used to cut surface glare in everything from eyeglasses and camera lenses to solar cells, TV screens and LED devices. Now researchers from Research Institute for Nuclear Problems of Belarusian State University in Belarus and Institut Jean Lamour-Université de Lorraine in France have developed a novel, low-cost, ultra-lightweight material that could be used as an effective anti-reflective surface for microwave radiation based on the eyes of moths.

The eyes of moths are covered with a periodic, hexagonal pattern of tiny bumps smaller than the wavelength of the incident light. They act as a continuous refractive index gradient, allowing the moths to see at night and avoid nocturnal predators, like the bat. The physiology also makes the moth eye one of the most effective antireflective coatings in nature. It has already successfully been mimicked by scientists for developing high-performance antireflective coatings for visible lights – albeit coatings that are often expensive to fabricate and difficult to customize.

The new material cuts down reflections from microwaves rather than from visible light – invisible energy from a different part of the energy spectrum. Blocking microwave reflection is an important application for precise microwave measurements, and the coating may be used as a radar absorbing material in stealth technology, a technique that makes make an airplane invisible to radar, or police traffic radar that uses microwaves to measure car speed.

Post link

Researchers study super-repellent surfaces for safer fruits, vegetables

Texas A&M AgriLife Research and the Texas A&M Engineering Experiment Station, TEES, were recently awarded a grant from the U.S. Department of Agriculture’s National Institute of Food and Agriculture to study and develop super-repellent and anti-fouling surfaces for foods.

The grant will be used in their collaboration to help ensure the safety of fresh food products, benefiting both consumers and the produce industry.

“There is a need to reduce those outbreaks associated with microbial contamination that may take place in different operations along the fresh produce chain,” said Dr. Luis Cisneros-Zevallos, AgriLife Research food scientist in College Station and co-principal investigator for the project. “The surfaces we are designing avoid cross-contamination and reduce the risk of biofilm formation.”

“In recent years, we have developed various types of nanotechnology-based coating with an intriguing combination of surface texture and chemistry to inhibit and prevent the attachment of microorganisms on plastics, metals, ceramic and glass at the laboratory scale,” said Dr. Mustafa Akbulut, TEES chemical engineer in College Station and principal investigator for the project.

Post link

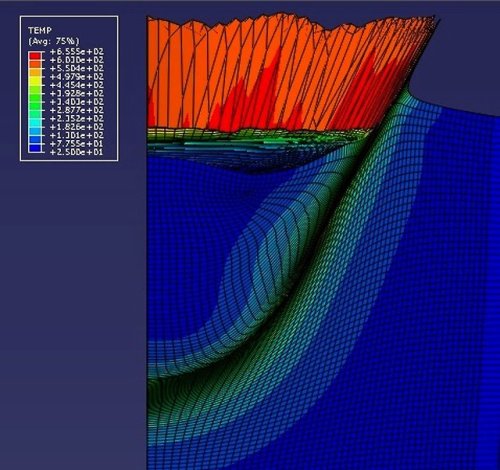

Splashdown: Supersonic cold metal bonding in 3-D

When a fragile surface requires a rock-hard, super-thin bonded metal coating, conventional manufacturing processes come up short. However, Cold Gas Dynamic Spray (CGDS) can do just that - with a big caveat. CGDS is enormously versatile, but is also very difficult to predict key aspects of the entire process. Now a temperature-based 3D model by Professor Tien-Chien Jen from the University of Johannesburg starts unlocking the mysteries of the CGDS film-growing process in the particle deposition zone.

Themodel is the first to connect the dots between particle impact velocity, energy transformation, and temperature rise in the particle impact zone, in three dimensions.

CGDS is already used extensively to manufacture or repair metal parts for large passenger airliners, as well as mobile technology and military equipment.

In the process, a de Laval nozzle sprays micron-sized metal particles over a short distance, typically 25mm, at a metal or polymer surface. The particles impact the surface at speeds ranging from 300 meters per second to 800 meters per second. As a frame of reference, the speed of sound is 343 meters per second.

Post link

New screen coating makes reading in sunlight a lot easier—the secret? Moth eyes

Screens on even the newest phones and tablets can be hard to read outside in bright sunlight. Inspired by the nanostructures found on moth eyes, researchers have developed a new antireflection film that could keep people from having to run to the shade to look at their mobile devices.

The antireflection film exhibits a surface reflection of just .23 percent, much lower than the iPhone’s surface reflection of 4.4 percent, for example. Reflection is the major reason it’s difficult to read a phone screen in bright sunlight, as the strong light reflecting off the screen’s surface washes out the display.

Researchers led by Shin-Tson Wu of the College of Optics and Photonics, University of Central Florida (CREOL), report on their new antireflection coating in Optica, The Optical Society’s journal for high impact research.

“Using our flexible anti-reflection film on smartphones and tablets will make the screen bright and sharp, even when viewed outside,” said Wu. “In addition to exhibiting low reflection, our nature-inspired film is also scratch resistant and self-cleaning, which would protect touch screens from dust and fingerprints.”

Post link

Copper coating on 3-D-printed plastic filters proposed as a pandemic fighter

In the ongoing fight against COVID-19, experts on microbiology and copper are recommending an expanded use of the metal to reduce the virus’s spread. So might copper be incorporated into the construction of masks, the universally accepted virus-fighting personal item?

That’s what Jing Zhang of the School of Engineering and Technology at IUPUI and a team of researchers are doing, using a copper coating on 3-D-printed plastic filters to create more-efficient masks and respirators.

“One study in 2015, funded by the U.S. Department of Defense, said that a copper alloy can kill 58 percent of infections,” said Zhang, an associate professor in the Department of Mechanical and Energy Engineering. “We can use copper plating to cover some frequently touched surfaces such as doorknobs and elevator buttons; that inspired me to see how we could combine what looks like almost a magic metal into a mask design.”

Post link