#defects

Superstrong Al alloys may change manufacturing processes for automobiles, aerospace devices

Purdue University researchers have developed a superstrong material that may change some manufacturing processes for the aerospace and automobile industries.

The Purdue team, led by Xinghang Zhang, a professor in Purdue’s School of Materials Engineering, created high-strength aluminum alloy coatings. According to Zhang, there is an increasing demand for such materials because of their advantages for automakers and aerospace industries.

“We have created a very durable and lightweight aluminum alloy that is just as strong as, and possibly stronger than, stainless steel,” Zhang said. “Our aluminum alloy is lightweight and provides flexibility that stainless steel does not in many applications.”

Another member of the Purdue team, Yifan Zhang, a graduate student in materials engineering, said the aluminum alloy they created could be used for making wear- and corrosion-resistant automobile parts such as engines and coatings for optical lenses for specialized telescopes in the aerospace industry.

Post link

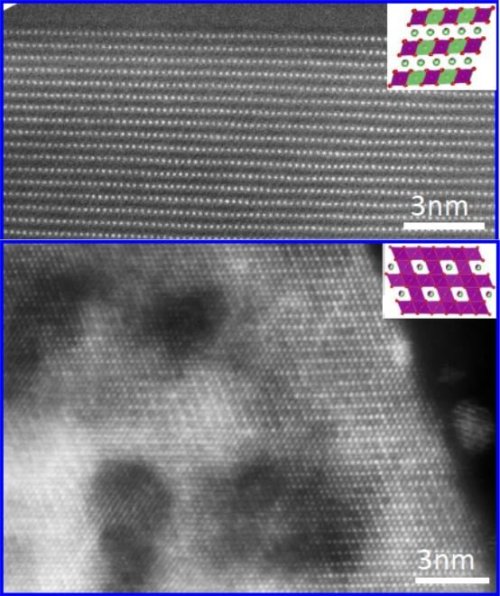

The culprit of some GaN defects could be nitrogen

As silicon-based semiconductors reach their performance limits, gallium nitride (GaN) is becoming the next go-to material to advance light-emitting diode (LED) technologies, high-frequency transistors and photovoltaic devices. Holding GaN back, however, is its high numbers of defects.

This material degradation is due to dislocations—when atoms become displaced in the crystal lattice structure. When multiple dislocations simultaneously move from shear force, bonds along the lattice planes stretch and eventually break. As the atoms rearrange themselves to reform their bonds, some planes stay intact while others become permanently deformed, with only half planes in place. If the shear force is great enough, the dislocation will end up along the edge of the material.

Layering GaN on substrates of different materials makes the problem that much worse because the lattice structures typically don’t align. This is why expanding our understanding of how GaN defects form at the atomic level could improve the performance of the devices made using this material.

A team of researchers has taken a significant step toward this goal by examining and determining six core configurations of the GaN lattice. They presented their findings in the Journal of Applied Physics.

Post link

Molecular mayhem at root of battery breakdown

Scientists at Pacific Northwest National Laboratory (PNNL) have uncovered a molecular game of musical chairs that hurts battery performance.

In an article published in Nature Nanotechnology, the researchers demonstrate how the excitation of oxygen atoms that contributes to better performance of a lithium-ion battery also triggers a process that leads to damage, explaining a phenomenon that has been a mystery to scientists.

The research pinpoints the science behind one barrier on the road to creating longer-lived, higher-capacity rechargeable lithium-ion batteries. It’s an unexpected finding about a process that takes place every day in the batteries that power cell phones, laptop computers, and electric cars.

Post link

Atomic imperfections move quantum communication network closer to reality

The work advances the possibility of applying quantum mechanical principles to existing optical fiber networks for secure communications and geographically distributed quantum computation. Prof. David Awschalom and his 13 co-authors announced their discovery in the June 23 issue of Physical Review X.

“Silicon carbide is currently used to build a wide variety of classical electronic devices today,” said Awschalom, the Liew Family Professor in Molecular Engineering at UChicago and a senior scientist at Argonne National Laboratory. “All of the processing protocols are in place to fabricate small quantum devices out of this material. These results offer a pathway for bringing quantum physics into the technological world.”

The findings are partly based on theoretical models of the materials performed by Awschalom’s co-authors at the Hungarian Academy of Sciences in Budapest. Another research group in Sweden’s Linköping University grew much of the silicon carbide material that Awschalom’s team tested in experiments at UChicago. And another team at the National Institutes for Quantum and Radiological Science and Technology in Japan helped the UChicago researchers make quantum defects in the materials by irradiating them with electron beams.

Post link

Symmetrical Binding for Topological States

A new technique creates defects in a topological acoustic system that don’t destroy the system’s chiral symmetry, protecting its topological states.

[…]

In a material with a so-called topologically protected state, particles—electrons, photons, or phonons, for example—can move around boundaries in the material without losing energy or being scattered. One way to make a material with such a state is to add into its lattice one or more defects that violate the lattice’s rotational symmetry—for example, disclinations (line defects). However, such defects can break the lattice’s chiral symmetry, which helps protect the topological state. Now, Yun Jing of Pennsylvania State University and colleagues propose and demonstrate a way to ensure chiral symmetry is preserved in the presence of such a defect [1].

Post link

Laser-based ultrasound detects defect-producing features in metal 3D printing

Lawrence Livermore National Laboratory (LLNL) researchers have developed a new all-optical ultrasound technique capable of performing on-demand characterization of melt tracks and detecting formation of defects in a popular metal 3D printing process.

In a paper published by Scientific Reports, lab researchers propose a diagnostic using surface acoustic waves (SAW), generated by laser-based ultrasound, that can reveal tiny surface and sub-surface defects in laser powder bed fusion (LPBF) metal 3D-printing. The team reported the system they developed can effectively and accurately evaluate laser melt lines—the tracks where the laser liquifies metal powder in LPBF printing—by scattering acoustic energy from melt lines, voids and surface features that can be quickly detected. The team validated the findings using optical microscopy and X-ray computed tomography (CT).

“We hope that this work demonstrates the potential for an all-optical ultrasound system capable of rapid, on-demand in situ characterization of LPBF processes and powders,” said LLNL engineer and principal investigator David Stobbe. “The demonstrated laser-based ultrasound, surface acoustic wave system showed excellent sensitivity to surface and near-surface features, including breaks in the LPBF melt line, metal surface splatter and subsurface air voids.”

Post link