#computational materials science

The culprit of some GaN defects could be nitrogen

As silicon-based semiconductors reach their performance limits, gallium nitride (GaN) is becoming the next go-to material to advance light-emitting diode (LED) technologies, high-frequency transistors and photovoltaic devices. Holding GaN back, however, is its high numbers of defects.

This material degradation is due to dislocations—when atoms become displaced in the crystal lattice structure. When multiple dislocations simultaneously move from shear force, bonds along the lattice planes stretch and eventually break. As the atoms rearrange themselves to reform their bonds, some planes stay intact while others become permanently deformed, with only half planes in place. If the shear force is great enough, the dislocation will end up along the edge of the material.

Layering GaN on substrates of different materials makes the problem that much worse because the lattice structures typically don’t align. This is why expanding our understanding of how GaN defects form at the atomic level could improve the performance of the devices made using this material.

A team of researchers has taken a significant step toward this goal by examining and determining six core configurations of the GaN lattice. They presented their findings in the Journal of Applied Physics.

Post link

Supercomputer predicts optical and thermal properties of complex hybrid materials

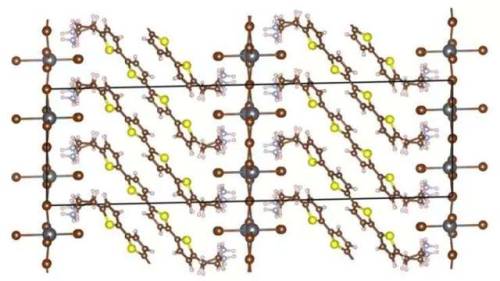

Materials scientists at Duke University computationally predicted the electrical and optical properties of semiconductors made from extended organic molecules sandwiched by inorganic structures.

These types of so-called layered “hybrid organic-inorganic perovskites"—or HOIPs—are popular targets for light-based devices such as solar cells and light-emitting diodes (LEDs). The ability to build accurate models of these materials atom-by-atom will allow researchers to explore new material designs for next-generation devices.

The results appeared online on October 4 in Physical Review Letters.

"Ideally we would like to be able to manipulate the organic and inorganic components of these types of materials independently and create semiconductors with new, predictable properties,” said David Mitzi, the Simon Family Professor of Mechanical Engineering and Materials Science at Duke. “This study shows that we are able to match and explain the experimental properties of these materials through complex supercomputer simulations, which is quite exciting.”

Post link

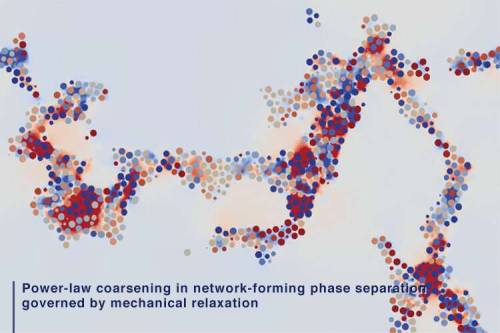

Discovery of a new law of phase separation

Researchers from Institute of Industrial Science at The University of Tokyo investigated the mechanism of phase separation into the two phases with very different particle mobilities using computer simulations. They found that slow dynamics of complex connected networks control the rate of demixing, which can assist in the design of new functional porous materials, like lithium-ion batteries.

According to the old adage, oil and water don’t mix. If you try to do it anyway, you will see the fascinating process of phase separation, in which the two immiscible liquids spontaneously “demix.” In this case, the minority phase always forms droplets. Contrary to this, the researchers found that if one phase has much slower dynamics than the other phase, even the minority phase form complex networks instead of droplets. For example, in phase separation of colloidal suspensions (or protein solutions), the colloid-rich (or protein-rich) phase with slow dynamics forms a space-spanning network structure. The network structure thickens and coarsens with time while having the remarkable property of looking similar over a range of length scales, so the individual parts resemble the whole.

Post link

Engineers develop new software tool to aid material modeling research

A new software tool can accelerate materials science research by cutting out tedious background research on material properties. Penn State and Sandia National Laboratories researchers recently debuted propSym, an open-source software on the programming platform MATLAB, to calculate the fundamental constants needed to describe the physical properties of solids, such as metals, ceramics or composites.

Researchers input a material’s physical characteristics and structure, and the program produces its fundamental property constants—key values researchers need to model various materials.

“Some physical models contain hundreds or thousands of redundant components, which can make the model overwhelming,” said Anubhav Roy, a doctoral student in engineering science and mechanics in the Penn State College of Engineering and first author on the paper. “The program is able to greatly reduce the number of components for any physical property that is connected to solids with inherent crystalline symmetry.”

Post link

Minimizing laser phase noise with machine learning

Ultra-precise lasers can be used for optical atomic clocks, quantum computers, power cable monitoring, and much more. But all lasers make noise, which researchers from DTU Fotonik want to minimize using machine learning.

The perfect laser does not exist. There will always be a bit of phase noise because the laser light frequency moves back and forth a little. Phase noise prevents the laser from producing light waves with the perfect steadiness that is otherwise a characteristic feature of the laser.

Most of the lasers we use on a daily basis do not need to be completely precise. For example, it is of no importance whether the frequency of the red laser light in the supermarket barcode scanners varies slightly when reading the barcodes. But for certain applications—for example in optical atomic clocks and optical measuring instruments—it is absolutely crucial that the laser is stable so that the light frequency does not vary.

One way of getting closer to an ultra-precise laser is if you can determine the phase noise. This may enable you to find a way of compensating for it, so that the result becomes a purer and more accurate laser beam.

Post link

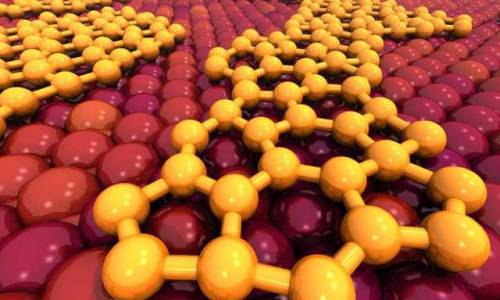

The flat and the curious

The remarkable properties of 2-D materials—made up of a single layer of atoms—have made them among the most intensely studied materials of our time. They have the potential to usher in a new generation of improved electronics, batteries and sensory devices, among other applications.

One obstacle to realizing applications of these materials is the cost and time needed for experimental studies. However, computer simulations are helping researchers overcome this challenge in order to accurately characterize material structures and functions at an accelerated pace.

At the U.S. Department of Energy’s (DOE) Argonne National Laboratory, researchers have simulated the growth of silicene, a 2-D material with attractive electronic properties. Their work, published in Nanoscale, delivers new and useful insights on the material’s properties and behavior and offers a predictive model for other researchers studying 2-D materials.

Going forward, this model can accelerate researchers’ understanding of 2-D materials, and bring us closer to realizing their applications within a wide range of industries.

Post link

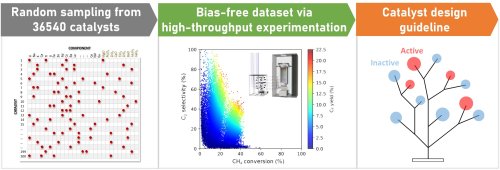

Thanks to machine learning, the future of catalyst research is now

To date, research in the field of combinatorial catalysts has relied on serendipitous discoveries of catalyst combinations. Now, scientists from Japan have streamlined a protocol that combines random sampling, high-throughput experimentation, and data science to identify synergistic combinations of catalysts. With this breakthrough, the researchers hope to remove the limits placed on research by relying on chance discoveries and have their new protocol used more often in catalyst informatics.

Catalysts, or their combinations, are compounds that significantly lower the energy required to drive chemical reactions to completion. In the field of combinatorial catalyst design, the requirement of synergy—where one component of a catalyst complements another—and the elimination of ineffective or detrimental combinations are key considerations. However, so far, combinatorial catalysts have been designed using biased data or trial-and-error, or serendipitous discoveries of combinations that worked. A group of researchers from Japan has now sought to change this trend by trying to devise a repeatable protocol that relied on a screening instrument and software-based analysis.

Post link

High-throughput computer model predicts diffusion data for the transport of light elements within solids

The diffusion of light elements into metals has been efficiently modeled by A*STAR researchers using a machine learning approach.

Solid-state diffusion, in which atoms migrate through the lattice of a host material, underpins a variety of important processes that range from undesirable (corrosion) to useful (metal-joining processes). In one mechanism called ‘interstitial diffusion,“ light elements, such as nitrogen, move through lattices made up of much bigger atoms, such as metals, by squeezing between them. Yingzhi Zeng and colleagues at the A*STAR Institute of High Performance Computing have now developed a rapid predictive model for this phenomenon.

"Typical examples of interstitial diffusion include surface hardening of steel through carburization or nitridation, and the diffusion of oxygen in titanium for the design of implant and aerospace alloys,” Zeng says. This process is important to understand, but particularly difficult to probe experimentally. The challenge stems from the heavy-duty specialized equipment that is often required, and because as Zeng explains, “most experimental techniques rely on surface measurements, and so are inherently limited to a few nanometers under the surface.”

Post link

Ancient art of kirigami meets AI for better materials design

Kirigami is the Japanese art of paper cutting. Likely derived from the Chinese art of jiǎnzhǐ, it emerged around the 7th century in Japan, where it was used to decorate temples. Still in practice today, the kirigami artist uses one piece of paper to cut decorative designs, like birds and fish or the more intricate and popular snowflake.

But, this ancient art, which relies on exacting cuts to determine or replicate patterns, is finding more modern and practical applications in electronics. Specifically, in the manufacture of 2D stretchable materials that can play host to wearable electronics, like electronic skins for health monitoring.

The process combines the art of kirigami with an artificial intelligence technique called autonomous reinforcement learning. And to better synchronize the old with the new, researchers from the University of Southern California use the computing power available to them at the U.S. Department of Energy’s (DOE) Argonne National Laboratory.

Post link

I am interested in learning more about computational thermodynamics and I am wondering if anyone can recommend some resources. I have looked a little online but there are a large number of textbooks and I want to make sure I get a good one.

Thanks!

Finding alternatives to diamonds for drilling

Diamonds aren’t just a girl’s best friend—they’re also crucial components for hard-wearing industrial components, such as the drill bits used to access oil and gas deposits underground. But a cost-efficient method to find other suitable materials to do the job is on the way.

Diamond is one of the only materials hard and tough enough for the job of constant grinding without significant wear, but as any imminent proposee knows, diamonds are pricey. High costs drive the search for new hard and superhard materials. However, the experimental trial-and-error search is itself expensive.

A simple and reliable way to predict new material properties is needed to facilitate modern technology development. Using a computational algorithm, Russian theorists have published just such a predictive tool in the Journal of Applied Physics, from AIP Publishing.

“Our study outlines a picture that can guide experimentalists, showing them the direction to search for new hard materials,” said the study’s first author Alexander Kvashnin, from the Skolkovo Institute of Science and Technology and Moscow Institute of Physics and Technology.

Post link

Splashdown: Supersonic cold metal bonding in 3-D

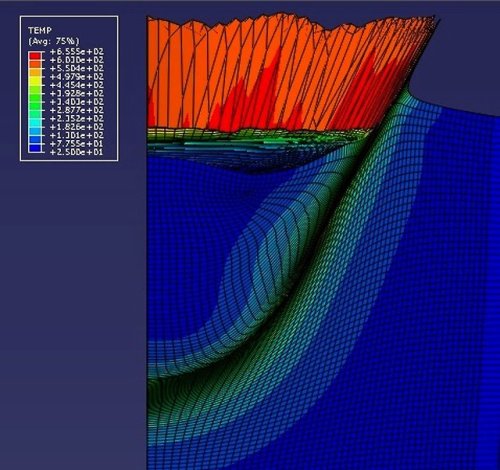

When a fragile surface requires a rock-hard, super-thin bonded metal coating, conventional manufacturing processes come up short. However, Cold Gas Dynamic Spray (CGDS) can do just that - with a big caveat. CGDS is enormously versatile, but is also very difficult to predict key aspects of the entire process. Now a temperature-based 3D model by Professor Tien-Chien Jen from the University of Johannesburg starts unlocking the mysteries of the CGDS film-growing process in the particle deposition zone.

Themodel is the first to connect the dots between particle impact velocity, energy transformation, and temperature rise in the particle impact zone, in three dimensions.

CGDS is already used extensively to manufacture or repair metal parts for large passenger airliners, as well as mobile technology and military equipment.

In the process, a de Laval nozzle sprays micron-sized metal particles over a short distance, typically 25mm, at a metal or polymer surface. The particles impact the surface at speeds ranging from 300 meters per second to 800 meters per second. As a frame of reference, the speed of sound is 343 meters per second.

Post link

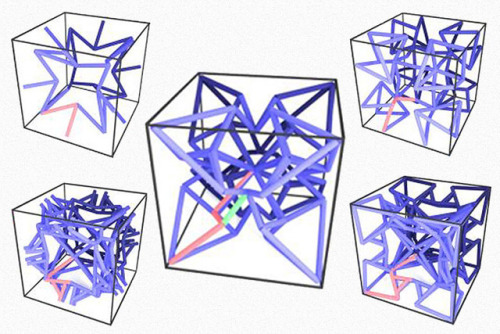

Engineers Develop Automated Process for Discovering Optimal Structure for Metamaterials

For decades, materials scientists have taken inspiration from the natural world. They’ll identify a biological material that has some desirable trait — such as the toughness of bones or conch shells — and reverse-engineer it. Then, once they’ve determined the material’s “microstructure,” they’ll try to approximate it in human-made materials.

Researchers at MIT’s Computer Science and Artificial Intelligence Laboratory have developed a new system that puts the design of microstructures on a much more secure empirical footing. With their system, designers numerically specify the properties they want their materials to have, and the system generates a microstructure that matches the specification.

The researchers have reported their results in Science Advances. In their paper, they describe using the system to produce microstructures with optimal trade-offs between three different mechanical properties. But according to associate professor of electrical engineering and computer science Wojciech Matusik, whose group developed the new system, the researchers’ approach could be adapted to any combination of properties.

“We did it for relatively simple mechanical properties, but you can apply it to more complex mechanical properties, or you could apply it to combinations of thermal, mechanical, optical, and electromagnetic properties,” Matusik says. “Basically, this is a completely automated process for discovering optimal structure families for metamaterials.”

Post link

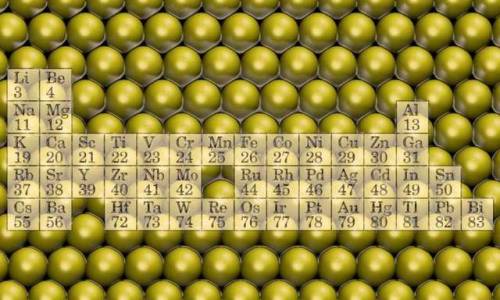

New research opening for atomically thin metal nanostructures

Researchers at the Nanoscience Center at the University of Jyväskylä, Finland, have made a new opening in nanomaterial research. Opening’s essence resides in the exclusive use of metallic elements in flat, atomically thin nanostructures.

The best known flat nanomaterial is graphene. Graphene is stable because the non-metallic element carbon prefers covalent, directional bonds that effectively cause structural planarity. Metallic bonds are less directional, whereby metals often coalesce into compact clusters. However, recent experiments suggest that, by using pores in other nanostructures, even metals can be stabilized into atomically thin planes.

Inspired by these experimental indications, researchers at the Nanoscience Center, University of Jyväskylä, used computer simulations to predict systematically the properties of atomically thin structures made exclusively from metallic elements.

“We made a new opening in material research, which was basic research, but highly rewarding as such,” says postdoctoral researcher Janne Nevalaita. “One could say that we hit on an untouched estate, bulldozed it and created a foundation. Now others can build solid scientific structures based on that foundation,” he continues.

Post link

Tuning exact ratios of two metals in a catalyst may enable new directions in catalysis science

In the last 20 years, there have been efforts to reduce fossil fuel use in plastics manufacturing, and, according to Penn State researchers, efficient, customizable catalytic reactions—where two metals are combined using a catalyst, or molecule that remains unchanged during a reaction—are an attractive alternative.

Researchers have found a way to make catalytic reactions less wasteful and more cost effective by controlling the placement of each atom on the catalyst surface. Controlling or customizing the catalysts cuts down on unneeded competitive reactions and isolates a successful, predictable reaction. These results were published in Nature Chemistry.

“By isolating an active metal in an inert host, and precisely controlling the exact ratio of the metals, we can get a targeted pattern of the two metal atoms,” said Michael Janik, Penn State professor of chemical engineering and co-principal investigator for the study.

Researchers used palladium, which served as the active catalyst component, and zinc, the inert host, to form an intermetallic, a compound with two or more types of metal atoms arranged in a repeating pattern.

Post link