#physics laboratory

Ion gauges on one of our deposition systems.

Ionization gauges are commonly used to measure pressure in high vacuum. They look and operate very much like a light bulb. Electrons are emitted from a central heated filament (the glowing part) and accelerated toward a helical wire or “grid” around the filament. Some of these electrons collide with gas molecules and ionize them. The ions are then attracted to a collector filament, creating a current which can be measured. The magnitude of the ion current depends on the pressure and composition of the gas.

Post link

Discarded AFM tips.

Atomic Force Microscopy, or AFM, is a technique by which a small mechanical probe is scanned across a sample to create a height map. This technique has very high resolution, less than a nanometer, depending on what kind of tip is being used, and can be done in ambient conditions (no need for vacuum). AFM is useful for getting roughness data and measuring film thickness, and can be combined with other microscopy techniques to get a complete picture of your device.

AFM probes often get damaged or dirty, resulting in “tip graveyards” like the one shown here.

Post link

Sample stage controls for an ion mill, allowing for rotation about two different axes.

Ion milling is a type of dry etch process used to remove parts of a sample by bombarding it with ions, typically argon, in a vacuum chamber. It can be thought of as an atomic sand blaster. Ions (the “grains of sand”) physically expel, or sputter, chunks of material from the surface. The sample is rotated to ensure uniform coverage.

Post link

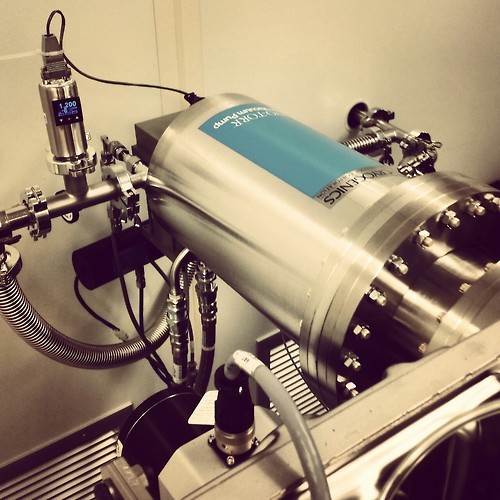

Cryopump on a sputter system.

Cryopumps are a common type of high vacuum pump. They operate by condensing or freezing gases in the vacuum chamber onto an array that is typically cooled down to 10-12 kelvin. Compressed helium gas enters a chamber below the condenser array, where a piston (the displacer) allows the gas to expand, removing heat from the system. The piston then pushes the helium out and back into a compressor, and the cycle repeats. The displacer and compressor in a cryopump make a distinctive rhythmic high pitched whistle that is a common sound in clean rooms and condensed matter physics labs.

Post link