#nanofab

A selection of evaporation sources in our cleanroom. Evaporation is a thin film deposition technique where the material is heated up to above its melting point in vacuum, typically using an electron beam. The molten material evaporates and is redeposited on your samples which are positioned near the source. Common materials that can be deposited using this technique include gold, copper, titanium, platinum, nickel, iron, silicon dioxide, and carbon.

Post link

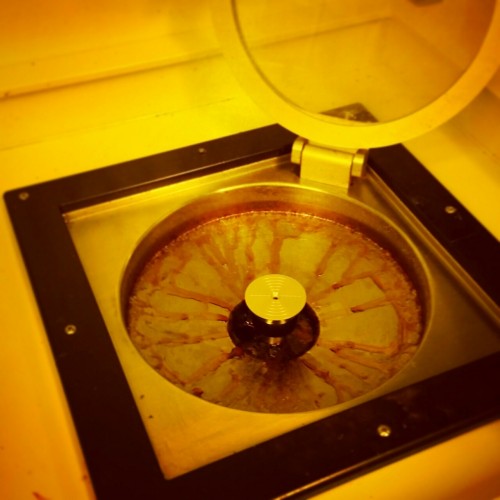

I spent part of the day today spinning photoresist. Photoresists are light sensitive chemicals used in photolithography. They are spun onto the sample at high speeds, using a tool like the one in the picture, to ensure an even coat. Yellow lighting is used in rooms dedicated to resist application and processing to prevent it from getting exposed. Once the resist is applied, a pattern can be transferred to your sample by exposing only certain areas to light.

Post link

Aluminum target for our sputter system. If you look closely you can see individual crystal grains.

Sputtering is a technique used to deposit thin films of material. The material source is called a target because it is bombarded with high energy atoms which remove bits of material that are then redeposited on your sample or wafer. The ring is a result of the magnetic field confining the plasma to that region.

Post link

Discarded AFM tips.

Atomic Force Microscopy, or AFM, is a technique by which a small mechanical probe is scanned across a sample to create a height map. This technique has very high resolution, less than a nanometer, depending on what kind of tip is being used, and can be done in ambient conditions (no need for vacuum). AFM is useful for getting roughness data and measuring film thickness, and can be combined with other microscopy techniques to get a complete picture of your device.

AFM probes often get damaged or dirty, resulting in “tip graveyards” like the one shown here.

Post link

Sample stage controls for an ion mill, allowing for rotation about two different axes.

Ion milling is a type of dry etch process used to remove parts of a sample by bombarding it with ions, typically argon, in a vacuum chamber. It can be thought of as an atomic sand blaster. Ions (the “grains of sand”) physically expel, or sputter, chunks of material from the surface. The sample is rotated to ensure uniform coverage.

Post link

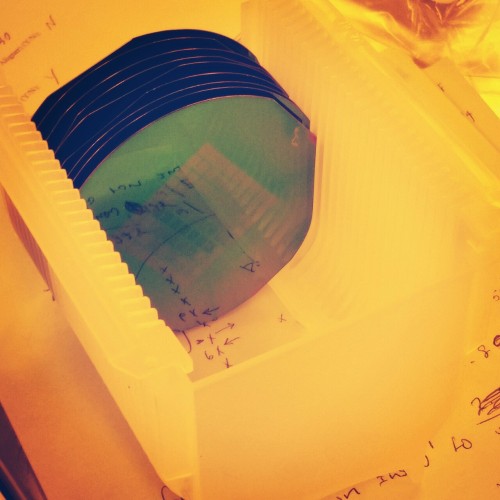

Patterned silicon wafers in the clean room.

Photolithography is a technique similar to photography used to make very small micron (~0.00004 inch) sized features. Wafers are coated in light sensitive chemicals called photoresist and then certain areas are exposed to light to create a pattern. The processing room is lit with yellow light to avoid exposing the resist. Photolithography is commonly used to make integrated circuits in electronics, but it is also used in basic research in fields such as physics, material science, engineering, and even biology.

Post link

Electron beam lithography is a technique used to write nanometer-size features using a narrow beam of electrons to trace out the desired pattern on your sample. This is a form of maskless lithography - custom patterns can be written without the need for a mask. However, ebeam lithography has a low throughput and it is expensive, making it impractical for industrial purposes. This form of lithography is mainly used in research, mask writing, and prototyping, rather than for mass producing devices.

In the past, I have used this system to make nanowires that are less than 100 nm wide. This is 1/1000th the diameter of a human hair!

Post link