#lab work

11 March 2022

Another lab day

New Shirt design up in my shop at moocyte.com!

Made using my own immunofluorescence microscopy images ♥️

A selection of evaporation sources in our cleanroom. Evaporation is a thin film deposition technique where the material is heated up to above its melting point in vacuum, typically using an electron beam. The molten material evaporates and is redeposited on your samples which are positioned near the source. Common materials that can be deposited using this technique include gold, copper, titanium, platinum, nickel, iron, silicon dioxide, and carbon.

Post link

Ion gauges on one of our deposition systems.

Ionization gauges are commonly used to measure pressure in high vacuum. They look and operate very much like a light bulb. Electrons are emitted from a central heated filament (the glowing part) and accelerated toward a helical wire or “grid” around the filament. Some of these electrons collide with gas molecules and ionize them. The ions are then attracted to a collector filament, creating a current which can be measured. The magnitude of the ion current depends on the pressure and composition of the gas.

Post link

Aluminum target for our sputter system. If you look closely you can see individual crystal grains.

Sputtering is a technique used to deposit thin films of material. The material source is called a target because it is bombarded with high energy atoms which remove bits of material that are then redeposited on your sample or wafer. The ring is a result of the magnetic field confining the plasma to that region.

Post link

Discarded AFM tips.

Atomic Force Microscopy, or AFM, is a technique by which a small mechanical probe is scanned across a sample to create a height map. This technique has very high resolution, less than a nanometer, depending on what kind of tip is being used, and can be done in ambient conditions (no need for vacuum). AFM is useful for getting roughness data and measuring film thickness, and can be combined with other microscopy techniques to get a complete picture of your device.

AFM probes often get damaged or dirty, resulting in “tip graveyards” like the one shown here.

Post link

Sample stage controls for an ion mill, allowing for rotation about two different axes.

Ion milling is a type of dry etch process used to remove parts of a sample by bombarding it with ions, typically argon, in a vacuum chamber. It can be thought of as an atomic sand blaster. Ions (the “grains of sand”) physically expel, or sputter, chunks of material from the surface. The sample is rotated to ensure uniform coverage.

Post link

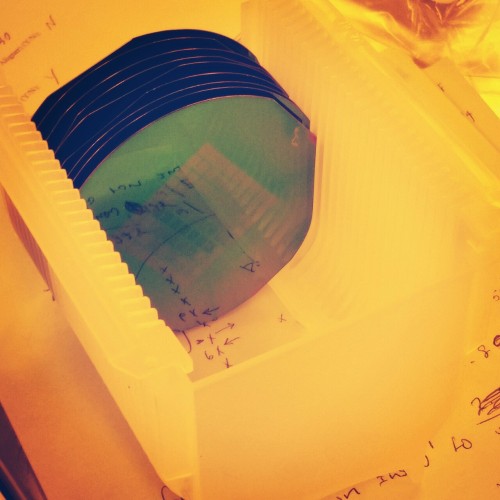

Patterned silicon wafers in the clean room.

Photolithography is a technique similar to photography used to make very small micron (~0.00004 inch) sized features. Wafers are coated in light sensitive chemicals called photoresist and then certain areas are exposed to light to create a pattern. The processing room is lit with yellow light to avoid exposing the resist. Photolithography is commonly used to make integrated circuits in electronics, but it is also used in basic research in fields such as physics, material science, engineering, and even biology.

Post link

Togging room for our cleanroom.

Cleanrooms, often used in industrial and scientific research, are environments with a controlled number of particles of a certain size per unit area in the air. This is to prevent contamination of samples during fabrication - large particles can ruin electrical devices and decrease yield.

To decrease the number of particles in the air, researchers are required to wear full body “bunny suits” and certain particle-generating items, such as pencils and normal paper, are not allowed. The room is slightly pressurized and the flow of air is controlled to push particles toward the floor and out of the cleanroom.

Our cleanroom is Class 1000, meaning there is approximately 1/100th the number of particles in regular air.

Post link

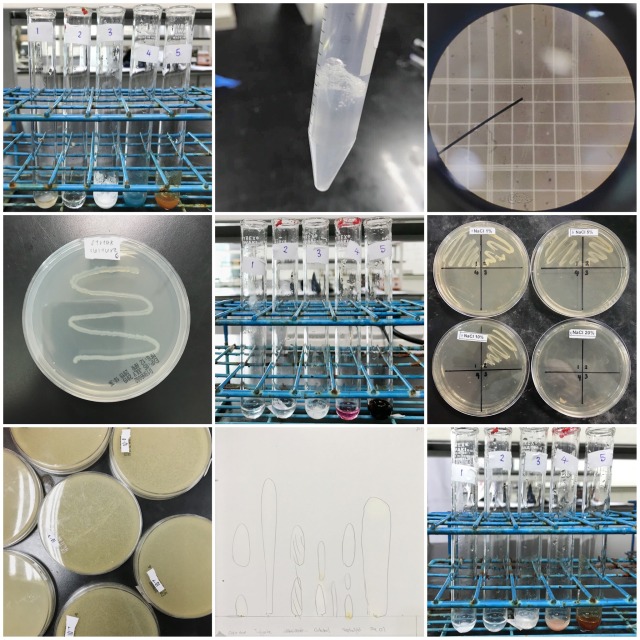

Here are some pictures that I’ve taken from my past laboratory experiments during the whole foundation year + my first year of BSc (Hons) Biotechnology in university! Had some pictures that are from failed / unsuccessful experiments (ㆀ˘・з・˘)

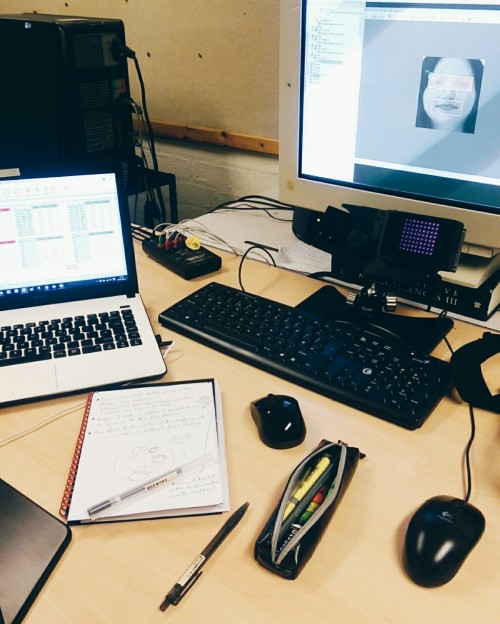

7am // Data analysis requires patience.

Working with the eye-tracker again and I’ve been inputting data for what feels like an eternity; I have >5,000 units to input.

Here’s something cool though: The eye-tracking camera on the right has an infrared illuminator (the square with the purple dots). I can’t actually see those dots with my naked eye (it’s pitch black, I’m looking at it right now and there’s no dots there). Turns out phone cameras are more sensitive to light than human eyes are, so it’s able to pick-up the infrared light that is ‘invisible’ to us. Am-a-zing!

Post link